×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Hyundai Parts

- Hyundai Accessories

My Garage

My Account

Cart

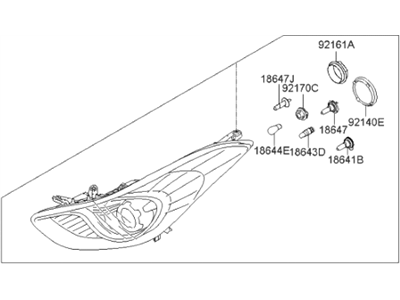

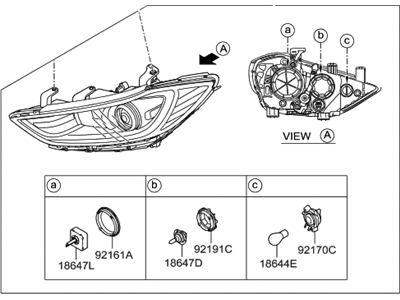

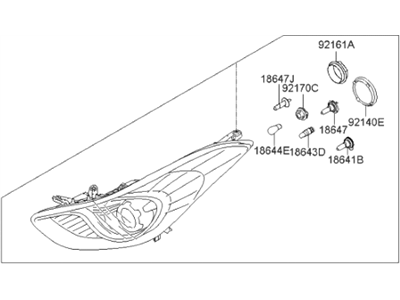

Genuine Hyundai Elantra Headlight

Headlamp- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

70 Headlights found

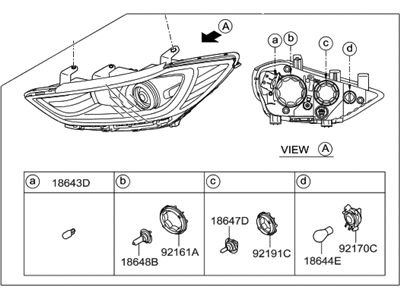

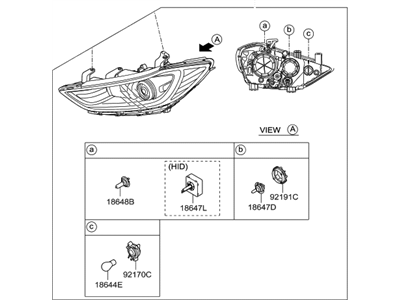

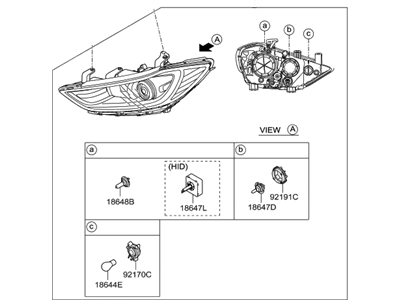

Hyundai Elantra Right Passenger Headlight

Part Number: 92102-F3000$504.00 MSRP: $714.32You Save: $210.32 (30%)Ships in 1-3 Business Days

Hyundai Elantra Headlamp Assembly, Left

Part Number: 92101-F2040$504.00 MSRP: $714.32You Save: $210.32 (30%)Ships in 1-3 Business Days

Hyundai Elantra Headlamp Assembly, Left

Part Number: 92101-F2050$504.00 MSRP: $714.32You Save: $210.32 (30%)Ships in 1-3 Business Days

Hyundai Elantra Right Side Headlight Halogen

Part Number: 92102-F3500$504.00 MSRP: $714.32You Save: $210.32 (30%)Ships in 1-3 Business Days

Hyundai Elantra Headlamp Assembly, Right

Part Number: 92102-F2040$504.00 MSRP: $714.32You Save: $210.32 (30%)Ships in 1-3 Business Days

Hyundai Elantra Headlamp Assembly, Left

Part Number: 92101-3X280$331.37 MSRP: $465.56You Save: $134.19 (29%)Ships in 1-3 Business Days

Hyundai Elantra Headlamp Assembly, Right

Part Number: 92102-3X280$331.37 MSRP: $465.56You Save: $134.19 (29%)Ships in 1-3 Business Days

Hyundai Elantra Headlamp Assembly, Right

Part Number: 92102-F2540$504.00 MSRP: $714.32You Save: $210.32 (30%)Ships in 1-3 Business Days

Hyundai Elantra Driver Side Headlight Assembly Composite

Part Number: 92101-3Y000$381.21 MSRP: $540.29You Save: $159.08 (30%)Ships in 1-2 Business Days

Hyundai Elantra Passenger Side Headlight Assembly Composite

Part Number: 92102-3Y000$380.75 MSRP: $539.65You Save: $158.90 (30%)Ships in 1-3 Business Days

Hyundai Elantra Headlamp Assembly, Left

Part Number: 92101-3X050$382.91 MSRP: $542.71You Save: $159.80 (30%)Ships in 1-2 Business Days

Hyundai Elantra Headlamp Assembly, Left

Part Number: 92101-F3010$504.00 MSRP: $714.32You Save: $210.32 (30%)Ships in 1-3 Business Days

Hyundai Elantra Headlamp Assembly, Left

Part Number: 92101-F3000$569.51 MSRP: $807.18You Save: $237.67 (30%)Ships in 1-3 Business Days

Hyundai Elantra Headlamp Assembly, Right

Part Number: 92102-3X050$382.91 MSRP: $542.71You Save: $159.80 (30%)Ships in 1-2 Business Days

Hyundai Elantra Headlamp Assembly, Left

Part Number: 92101-F2300$1227.46 MSRP: $1755.11You Save: $527.65 (31%)Ships in 1-3 Business Days

Hyundai Elantra Passenger Side Headlight Assembly

Part Number: 92102-3X450$884.96 MSRP: $1265.39You Save: $380.43 (31%)Ships in 1-3 Business DaysHyundai Elantra Left Driver Side Halogen Headlamp

Part Number: 92101-F3500$504.00 MSRP: $714.32You Save: $210.32 (30%)Ships in 1-3 Business DaysHyundai Elantra Driver Headlight Halogen Korean Built

Part Number: 92101-F2540$504.00 MSRP: $714.32You Save: $210.32 (30%)Ships in 1-3 Business DaysHyundai Elantra Right Passenger Side Headlight

Part Number: 92102-F2050$569.51 MSRP: $807.18You Save: $237.67 (30%)Ships in 1-2 Business DaysHyundai Elantra Headlamp Assembly, Right

Part Number: 92102-F3010$569.51 MSRP: $807.18You Save: $237.67 (30%)Ships in 1-3 Business Days

| Page 1 of 4 |Next >

1-20 of 70 Results

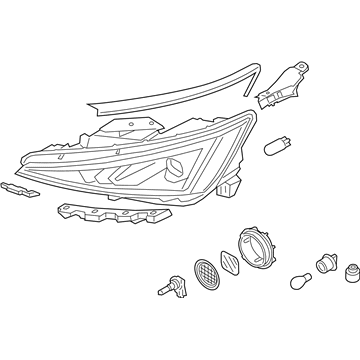

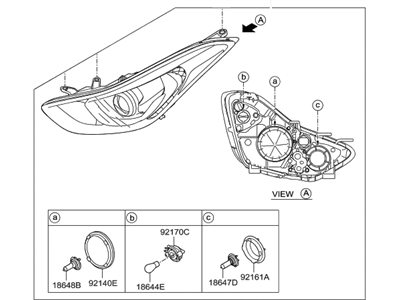

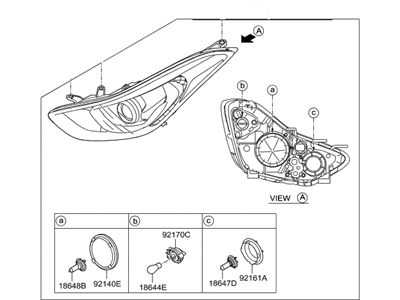

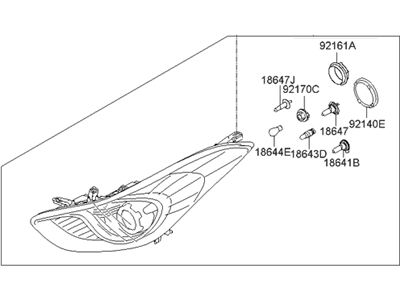

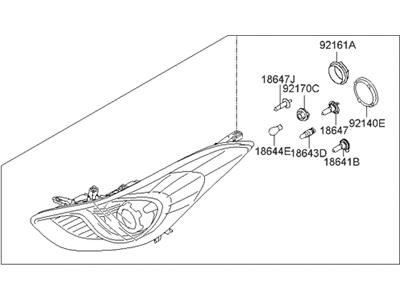

Hyundai Elantra Headlight

The Headlight is a vital part that profoundly contributes to the improvement of its features and safety of this small car recognized for durability. Playing the role of streetlights leading the way, these Headlights come in different choices such as halogen, LED, and Xenon bulbs, although modern Hyundai Elantra models are beginning to incorporate more advanced LED headlamps. The Elantra Headlight offers two distinct modes: low beam for short distances and high beam for longer distances, which enhances the ability of drivers to drive during the night or in cases of wet or foggy weather. The Headlight can be perfectly integrated into different versions of Hyundai Elantra models; thus, it is significant for enhancing the desired level of illumination, which is why it is crucial to upgrade to it. In the past years, there have been modifications on the Hyundai Elantra, and some of them included varied headlighting including projectors and halo headlamps, not only that bring illuminations but also design the look of the car. Switching of the beam is also automatic, and the construction of the Headlight is made to be more durable in the market. Problems such as dimming or flickering are clear indications it might be time for a replacement; hence it is affordable for drivers. Lastly, the Headlight contributes largely in making the Hyundai Elantra a more effective and safer vehicle on the roads to meet the desirable reputation of the Hyundai Elantra among car enthusiasts.

If you are looking for affordable high-quality OEM Hyundai Elantra Headlight, then you have come to the prime place. Our website provides a large amount of genuine Hyundai Elantra Headlight at unbeatable prices. All our parts come backed with the manufacturer's warranty.

Hyundai Elantra Headlight Parts Questions & Experts Answers

- Q: How should headlights be aimed correctly to ensure safety on Hyundai Elantra?A:The lighting devices particularly the headlights must be properly aligned such that they cannot cause inconvenience to other road users and at the same ensure adequate illumination of the road ahead. The aim should be tested at least once a year or when a new headlight has been fitted or there has been a change of the front-end body work. The process is only advisable for the short-term and should only be done so until a specialist can make the necessary alterations. The headlights have two adjusting screws: the vertical screw is easily located at the top of the unit and the horizontal screw is placed at the back of the housing and both need a Phillips screwdriver for turning. First, park the vehicle in a flat ground and facing a wall where there is no graph or design, then place a vertical masking tape that corresponds to the center of the car and both headlights. A horizontal tape line should also be placed in reference with the centerline of the head lights preferably when the car is parked slightly at a distance of couple of inches from the test surface for easy alignment of the tapes. The vehicle should be parked 25 feet away from the wall and leveled, with RPM between 3000 and 3500 with half tank of gas and no load. For Low beam adjustments the high intensity area should be positioned two inches below the HC line located two inches to the side of the HL vertical line away from the traffic coming in the opposite direction The Low beam is to be adjusted by utilizing either the top screw for lowering or raising the beam or the inside screw for adjusting it to the left or the right. Where the high beams are on, the high-intensity area should be placed just slightly below the straight line and noting that low beams are more used often and very essential for safety. It is recommended that the headlights should be correctly set by a professional centre as soon as it is possible.

Related Hyundai Elantra Parts

Browse by Year

2023 Headlight 2022 Headlight 2021 Headlight 2020 Headlight 2019 Headlight 2018 Headlight 2017 Headlight 2016 Headlight 2015 Headlight 2014 Headlight 2013 Headlight 2012 Headlight 2011 Headlight 2010 Headlight 2009 Headlight 2008 Headlight 2007 Headlight 2006 Headlight 2005 Headlight 2004 Headlight 2003 Headlight 2002 Headlight 2001 Headlight 2000 Headlight 1999 Headlight 1998 Headlight 1997 Headlight 1996 Headlight 1995 Headlight 1994 Headlight 1993 Headlight 1992 Headlight 1991 Headlight