×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Hyundai Parts

- Hyundai Accessories

My Garage

My Account

Cart

Genuine Hyundai Elantra Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

22 Oil Pans found

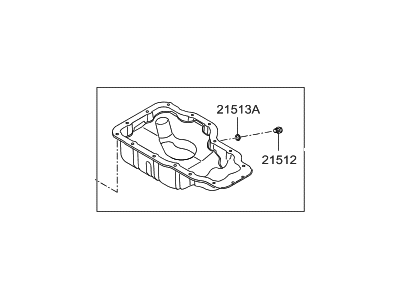

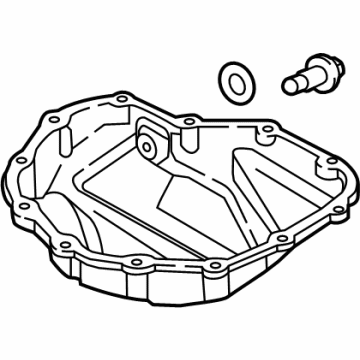

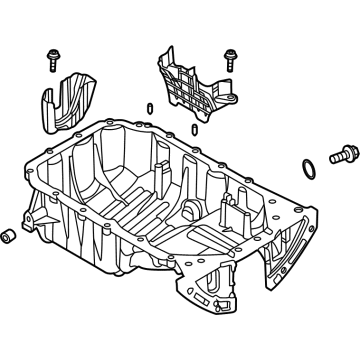

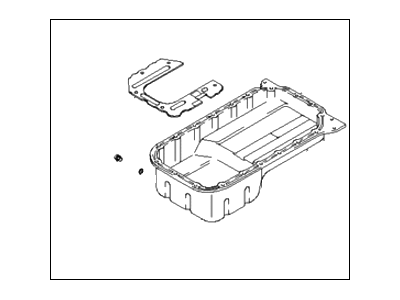

Hyundai Elantra Pan Assembly-Engine Oil

Part Number: 21510-2E023$89.97 MSRP: $126.40You Save: $36.43 (29%)Ships in 1-3 Business Days

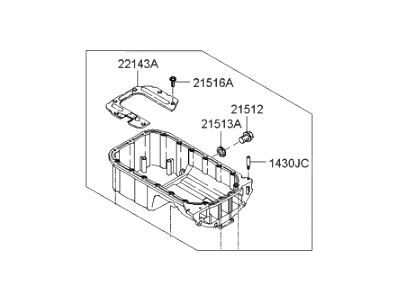

Hyundai Elantra Pan Assembly-Engine Oil

Part Number: 21510-2B700$34.73 MSRP: $48.37You Save: $13.64 (29%)Ships in 1-3 Business Days

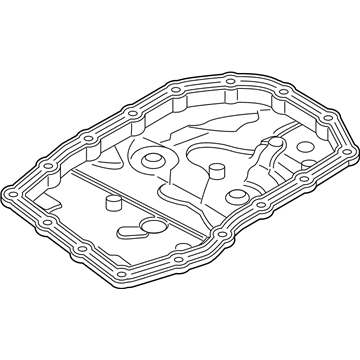

Hyundai Elantra Pan Assembly-Engine Oil

Part Number: 21510-2E022$89.97 MSRP: $126.40You Save: $36.43 (29%)Ships in 1-3 Business Days

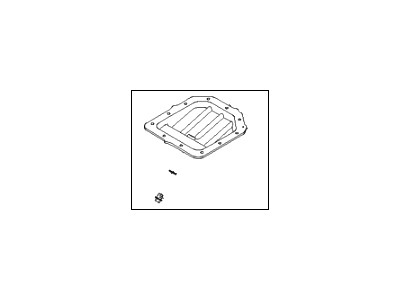

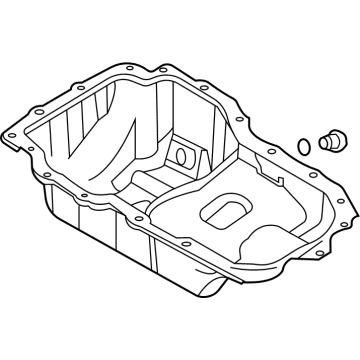

Hyundai Elantra Pan Assembly-Oil,Lower

Part Number: 21510-23700$39.93 MSRP: $55.61You Save: $15.68 (29%)Ships in 1-3 Business Days

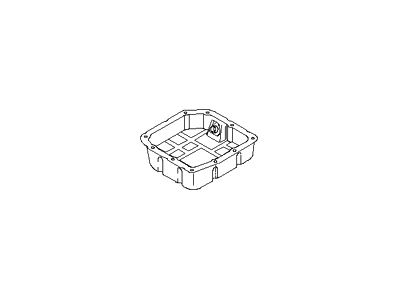

Hyundai Elantra Pan Assembly-Engine Oil

Part Number: 21520-23700$248.48 MSRP: $349.11You Save: $100.63 (29%)Ships in 1-3 Business DaysHyundai Elantra Pan Assembly-Engine Oil

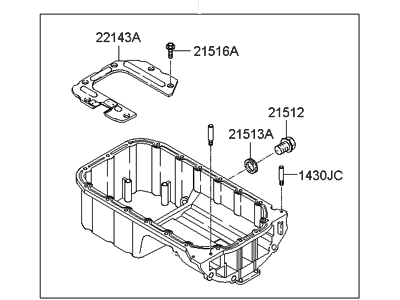

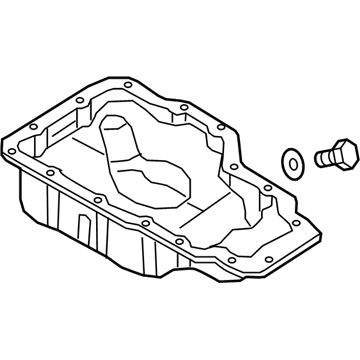

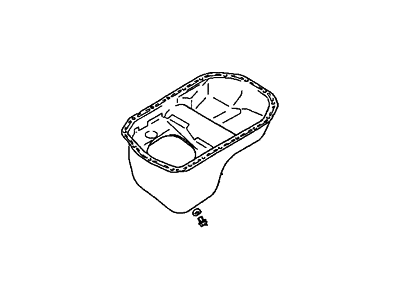

Part Number: 21510-03HA0$49.49 MSRP: $68.94You Save: $19.45 (29%)Ships in 1-3 Business DaysHyundai Elantra Pan Assembly-Engine Oil

Part Number: 21520-23604$279.17 MSRP: $392.23You Save: $113.06 (29%)Ships in 1-2 Business DaysHyundai Elantra Pan Assembly-Oil

Part Number: 48280-2H000$28.67 MSRP: $39.94You Save: $11.27 (29%)Ships in 1-3 Business DaysHyundai Elantra Pan Assembly-Engine Oil

Part Number: 21510-2M800$65.71 MSRP: $92.32You Save: $26.61 (29%)Ships in 1-3 Business DaysHyundai Elantra Pan Assembly-Engine Oil

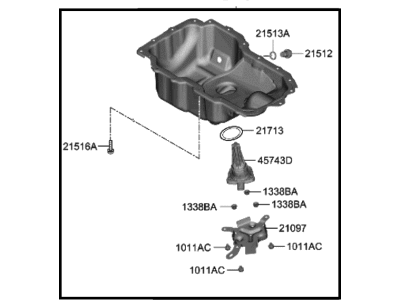

Part Number: 21510-2J001$260.97 MSRP: $366.66You Save: $105.69 (29%)Ships in 1-3 Business DaysHyundai Elantra Pan Assembly-Engine Oil

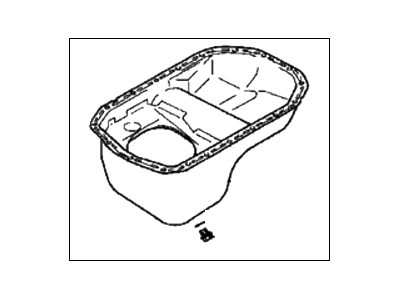

Part Number: 21510-2E040$89.97 MSRP: $126.40You Save: $36.43 (29%)Ships in 1-3 Business DaysHyundai Elantra PAN ASSY-ENGINE OIL

Part Number: 21510-2M870$141.51 MSRP: $198.82You Save: $57.31 (29%)Ships in 1-3 Business DaysHyundai Elantra Pan Assembly-Engine Oil

Part Number: 21510-03800$47.01 MSRP: $65.48You Save: $18.47 (29%)Ships in 1-3 Business DaysHyundai Elantra PAN ASSY-ENGINE OIL

Part Number: 21510-2J100$292.40 MSRP: $410.81You Save: $118.41 (29%)Ships in 1-3 Business DaysHyundai Elantra Pan Assembly-Engine Oil

Part Number: 21520-23502$279.17 MSRP: $392.23You Save: $113.06 (29%)Ships in 1-3 Business DaysHyundai Elantra Pan Assembly-Engine Oil

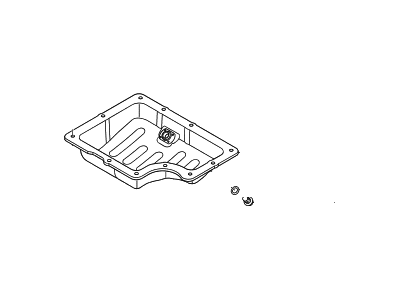

Part Number: 21520-23601$279.17 MSRP: $392.23You Save: $113.06 (29%)Ships in 1-3 Business DaysHyundai Elantra Pan Assembly-Engine Oil

Part Number: 21520-23602$279.17 MSRP: $392.23You Save: $113.06 (29%)Ships in 1-3 Business DaysHyundai Elantra Pan Assembly-Engine Oil

Part Number: 21510-33010$84.65 MSRP: $118.94You Save: $34.29 (29%)Ships in 1-3 Business DaysHyundai Elantra Pan Assembly-Engine Oil

Part Number: 21510-33430$84.65 MSRP: $118.94You Save: $34.29 (29%)Ships in 1-3 Business DaysHyundai Elantra Pan Assembly-Engine Oil

Part Number: 21510-33431$84.65 MSRP: $118.94You Save: $34.29 (29%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 22 Results

Hyundai Elantra Oil Pan

If you are looking for affordable high-quality OEM Hyundai Elantra Oil Pan, then you have come to the prime place. Our website provides a large amount of genuine Hyundai Elantra Oil Pan at unbeatable prices. All our parts come backed with the manufacturer's warranty.

Hyundai Elantra Oil Pan Parts Questions & Experts Answers

- Q: How to remove and insatall the oil pan on Hyundai Elantra?A:For removing the oil pan, turn on the parking brake and apply the wheel chocks on the rear wheels and then lift the front end of the car and put it on sturdy jackstands. For models from 2001 and later, there is a splash shield below the oil filter; remove the required bolts to release it. Dispose with the engine oil and also remove the oil dipstick, if any from the engine. On most models, there is a need to remove the exhaust system section beneath the engine; For 2001+ models, in a similar manner to the above explanation, unscrew the flange bolts and nuts of the catalyst to exhaust pipe, in addition to exhaust pipe bracket bolt. For the models from 1996 to 2000, unbolt the flywheel/driveplate access cover and the engine block-to-transaxle reinforcement bracket. Subsequently, the oil pan bolts should be unscrewed and the oil pan should be unbolted, the putty knife or a screwdriver might be necessary to ease the process since you should not harm the contact surfaces. For installating, remove the old sealant from the block and also from the oil pan, and also clean the joint surfaces and also the threaded bolt holes. Check the oil pan flange for bending and the OPR oil pump pick-up tube assembly for cracks or blockages, replace pick-up tube assembly with new O-ring or gasket if has been removed. Run a 3/16-inch bead of RTV sealant on the oil pan flange, set the oil pan in place and screw the bolts by hand while loosely tightening them. Torque all the bolts from the center towards the periphery for the next stage, the flywheel/ driveplate access cover and also the engine block to transaxle reinforcement bracket with the bolts being tightly fixed in place. The other steps of installation are the reversal of the removal process and one hour is given for the curing of the sealant before the addition of oil. Last but not least, start the engine and observe and look at the dials for oil pressure and ensure there are no signs of oil leaks.

Related Hyundai Elantra Parts

Browse by Year

2023 Oil Pan 2022 Oil Pan 2021 Oil Pan 2020 Oil Pan 2019 Oil Pan 2018 Oil Pan 2017 Oil Pan 2016 Oil Pan 2015 Oil Pan 2014 Oil Pan 2013 Oil Pan 2012 Oil Pan 2011 Oil Pan 2010 Oil Pan 2009 Oil Pan 2008 Oil Pan 2007 Oil Pan 2006 Oil Pan 2005 Oil Pan 2004 Oil Pan 2003 Oil Pan 2002 Oil Pan 2001 Oil Pan 2000 Oil Pan 1999 Oil Pan 1998 Oil Pan 1997 Oil Pan 1996 Oil Pan 1995 Oil Pan 1994 Oil Pan 1993 Oil Pan 1992 Oil Pan 1991 Oil Pan