×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Hyundai Parts

- Hyundai Accessories

My Garage

My Account

Cart

Genuine Hyundai Santa Fe Engine Mount

Engine Motor Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

43 Engine Mounts found

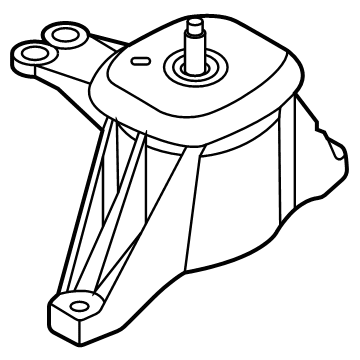

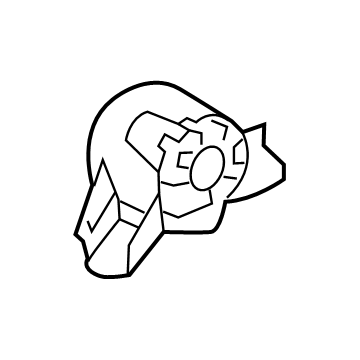

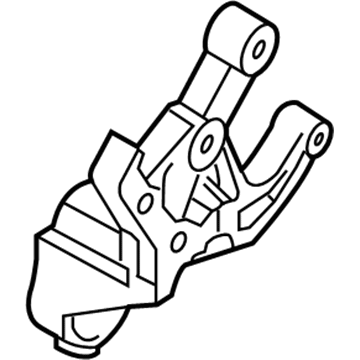

Hyundai Santa Fe Engine Mounting Bracket Assembly

Part Number: 21810-2W200$341.88 MSRP: $484.55You Save: $142.67 (30%)Ships in 1-3 Business Days

Hyundai Santa Fe Engine Mounting Bracket Assembly

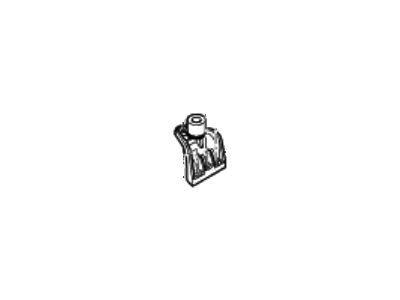

Part Number: 21810-2P100$401.96 MSRP: $569.71You Save: $167.75 (30%)Ships in 1-3 Business DaysHyundai Santa Fe Engine Support Bracket Assembly

Part Number: 21670-2GGB1$100.74 MSRP: $141.53You Save: $40.79 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Bracket Assembly-Engine MTG

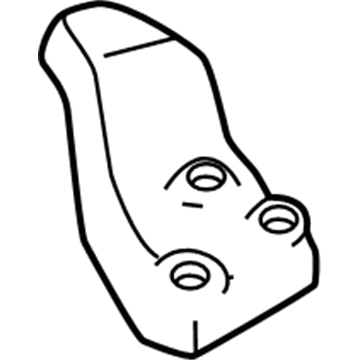

Part Number: 21810-L1150$247.67 MSRP: $347.97You Save: $100.30 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Engine Mounting Bracket Assembly

Part Number: 21810-26500$318.80 MSRP: $447.90You Save: $129.10 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Engine Mounting Bracket Assembly

Part Number: 21810-S1000$395.27 MSRP: $560.23You Save: $164.96 (30%)Ships in 1-3 Business DaysHyundai Santa Fe Engine Support Bracket Assembly

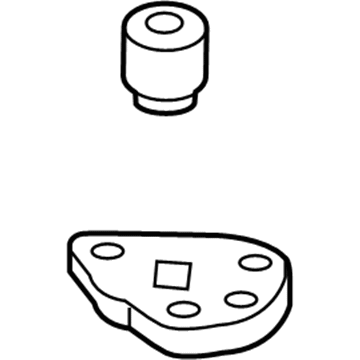

Part Number: 21670-2G000$64.13 MSRP: $90.10You Save: $25.97 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Engine Support Bracket, Upper

Part Number: 21612-39003$254.17 MSRP: $357.10You Save: $102.93 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Transmission Mounting Bracket Assembly

Part Number: 21830-S1100$289.73 MSRP: $407.06You Save: $117.33 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Engine Mounting Bracket Assembly

Part Number: 21820-2B100$85.49 MSRP: $120.11You Save: $34.62 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Engine Mounting Support Bracket

Part Number: 21815-26600$104.98 MSRP: $147.50You Save: $42.52 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Engine Mounting Bracket Assembly

Part Number: 21820-2W100$125.10 MSRP: $175.76You Save: $50.66 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Engine Mounting Support Bracket

Part Number: 21825-C5000$147.37 MSRP: $207.05You Save: $59.68 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Engine Mounting Bracket

Part Number: 21811-D4000$10.37 MSRP: $13.40You Save: $3.03 (23%)Ships in 1-3 Business DaysHyundai Santa Fe Engine Mounting Bracket

Part Number: 21811-26850$38.90 MSRP: $54.18You Save: $15.28 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Engine Mounting Bracket Assembly

Part Number: 21810-26850$351.08 MSRP: $497.60You Save: $146.52 (30%)Ships in 1-3 Business DaysHyundai Santa Fe Engine Mounting Bracket Assembly

Part Number: 21810-2P000$401.96 MSRP: $569.71You Save: $167.75 (30%)Ships in 1-3 Business DaysHyundai Santa Fe Bracket Assembly-Transmission MTG

Part Number: 21830-P2250$189.68 MSRP: $266.50You Save: $76.82 (29%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 43 Results

Hyundai Santa Fe Engine Mount

If you are looking for affordable high-quality OEM Hyundai Santa Fe Engine Mount, then you have come to the prime place. Our website provides a large amount of genuine Hyundai Santa Fe Engine Mount at unbeatable prices. All our parts come backed with the manufacturer's warranty.

Hyundai Santa Fe Engine Mount Parts Questions & Experts Answers

- Q: What actions are necessary if the engine mount is broken or deteriorated on Hyundai Santa Fe?A:Powertrain mounts are rarely an issue but a damaged or worn one must be repaired at the soonest time possible for it causes external fatigue on other driveline products. While checking the engine or transaxle mount the weight has to be taken off the mounts by lifting the engine or transaxle slightly. Start by lifting the vehicle using jack and properly supporting it with jack stands then, if it has an engine splash shield then remove it, then place the jack below the engine Oil Pan and put a large wooden plank in-between the jack and the oil pan. Slowly lift the engine up from the stands just enough to take the weight off the mounts, but ensure that the wood block is not underneath the oil drain plug. In this case it is important not to lean any part of the body on the car once the car is only being held up by a jack. Check for cracks in the mounts as well as any hardened rubber or separation from the bushing in the middle of the mount. Look for some relative movement between the mount plates and the engine or frame, with a large screwdriver or pry bar and try to push on the mounts. If there is any movement observed stop the engine and fasten the bolts of the mount. For replacement, all engine mounts are replaced in similar procedure in the following way-supporting the weight of the engine by using the jack, then relieve all the force from the mount which is to be replaced. Unscrew the bolts on both sides of the mount and discharge the mount form the car. Last of all, fit the new mount to the vehicle's body and torque the bolts to the manufacturer's recommended specifications.

Related Hyundai Santa Fe Parts

Browse by Year

2023 Engine Mount 2022 Engine Mount 2021 Engine Mount 2020 Engine Mount 2019 Engine Mount 2018 Engine Mount 2017 Engine Mount 2016 Engine Mount 2015 Engine Mount 2014 Engine Mount 2013 Engine Mount 2012 Engine Mount 2011 Engine Mount 2010 Engine Mount 2009 Engine Mount 2008 Engine Mount 2007 Engine Mount 2006 Engine Mount 2005 Engine Mount 2004 Engine Mount 2003 Engine Mount 2002 Engine Mount 2001 Engine Mount 2000 Engine Mount