×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Hyundai Parts

- Hyundai Accessories

My Garage

My Account

Cart

Genuine Hyundai Sonata ABS Sensor

ABS Wheel Speed Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

58 ABS Sensors found

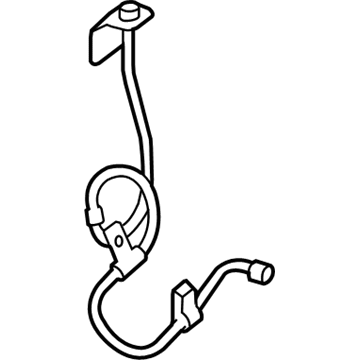

Hyundai Sonata Cable Assembly-ABS.EXT,RH

Part Number: 59930-C1000$219.08 MSRP: $307.81You Save: $88.73 (29%)Ships in 1-3 Business Days

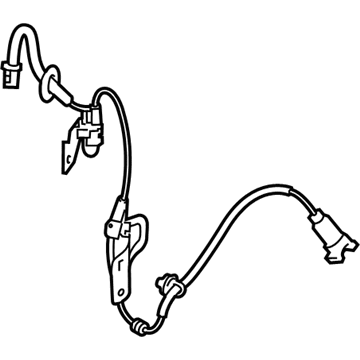

Hyundai Sonata Sensor Assembly-Front ABS.RH

Part Number: 59830-C1000$268.55 MSRP: $377.31You Save: $108.76 (29%)Ships in 1-3 Business Days

Hyundai Sonata Sensor Assembly-Front ABS.RH

Part Number: 59830-3Q000$268.55 MSRP: $377.31You Save: $108.76 (29%)Ships in 1-2 Business Days

Hyundai Sonata Cable Assembly-ABS.EXT,LH

Part Number: 59910-C1000$210.77 MSRP: $296.13You Save: $85.36 (29%)Ships in 1-2 Business Days

Hyundai Sonata Sensor Assembly-Front ABS.LH

Part Number: 59810-C1000$268.55 MSRP: $377.31You Save: $108.76 (29%)Ships in 1-3 Business Days

Hyundai Sonata Sensor-Abs Rear Wheel ,LH

Part Number: 59910-3K001$234.07 MSRP: $328.85You Save: $94.78 (29%)Ships in 1-3 Business Days

Hyundai Sonata Sensor-Abs Rear Wheel ,RH

Part Number: 59930-3K001$234.07 MSRP: $328.85You Save: $94.78 (29%)Ships in 1-3 Business DaysHyundai Sonata Sensor Assembly-Front ABS.LH

Part Number: 59810-3Q000$271.08 MSRP: $380.85You Save: $109.77 (29%)Ships in 1-3 Business DaysHyundai Sonata Sensor-Abs Front Wheel ,LH

Part Number: 59810-3K000$260.93 MSRP: $366.60You Save: $105.67 (29%)Ships in 1-3 Business DaysHyundai Sonata Sensor Assembly-Front ABS.LH

Part Number: 59810-3S900$260.93 MSRP: $366.60You Save: $105.67 (29%)Ships in 1-3 Business DaysHyundai Sonata Sensor-Abs Front Wheel ,RH

Part Number: 59830-3K000$260.93 MSRP: $366.60You Save: $105.67 (29%)Ships in 1-3 Business DaysHyundai Sonata Sensor Assembly-Front ABS.LH

Part Number: 59810-3S300$260.93 MSRP: $366.60You Save: $105.67 (29%)Ships in 1-3 Business DaysHyundai Sonata Sensor Assembly-Front ABS.RH

Part Number: 59830-3S300$260.93 MSRP: $366.60You Save: $105.67 (29%)Ships in 1-3 Business DaysHyundai Sonata Sensor Assembly-Front ABS.RH

Part Number: 59830-3S900$260.93 MSRP: $366.60You Save: $105.67 (29%)Ships in 1-3 Business DaysHyundai Sonata Cable Assembly-ABS.EXT,LH

Part Number: 59910-C1100$210.77 MSRP: $296.13You Save: $85.36 (29%)Ships in 1-3 Business DaysHyundai Sonata Cable Assembly-ABS.EXT,LH

Part Number: 59910-C1200$210.77 MSRP: $296.13You Save: $85.36 (29%)Ships in 1-3 Business DaysHyundai Sonata Cable Assembly-ABS.EXT,RH

Part Number: 59930-C1100$210.77 MSRP: $296.13You Save: $85.36 (29%)Ships in 1-3 Business DaysHyundai Sonata Sensor-Abs Front Wheel ,RH

Part Number: 59830-0A000$246.88 MSRP: $346.85You Save: $99.97 (29%)Ships in 1-2 Business DaysHyundai Sonata Sensor-Abs Rear Wheel ,RH

Part Number: 95685-34001$209.84 MSRP: $294.82You Save: $84.98 (29%)Ships in 1-3 Business DaysHyundai Sonata Sensor-Abs Rear Wheel ,RH

Part Number: 95685-34500$209.84 MSRP: $294.82You Save: $84.98 (29%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 58 Results

Hyundai Sonata ABS Sensor

If you are looking for affordable high-quality OEM Hyundai Sonata ABS Sensor, then you have come to the prime place. Our website provides a large amount of genuine Hyundai Sonata ABS Sensor at unbeatable prices. All our parts come backed with the manufacturer's warranty.

Hyundai Sonata ABS Sensor Parts Questions & Experts Answers

- Q: How to Check and Replace the ABS Control Module and ABS Sensor on Hyundai Sonata?A:ABS is the anti-lock braking system acquiring and managing the tighten angle of each wheel to keep vehicle steerability, directional stability and the best possible deceleration based on severe brake usage and road surfaces so as to stop wheel locking up. The system involves the hydraulic electric control section with the hydraulic actuator meeting located in the engine assembly of the car and containing the hydraulic electric pump and the hydraulic solenoid valves. The electric pump working as a hydraulic pump to develop the pressure needed to charge the reservoirs and the solenoid valve is use to control the pressure in the brake line during the operation. The ABS computer processes data from the wheels speed sensor and controls hydraulic line pressure and checks for failures in the system. The electrical signals that are generated depending on the wheel rotational speed are gotten from specific speed sensors; the front speed sensors are fixed to the steering knuckles while the rear one is fixed to the rear suspension hub carriers. Wherever Dashboard warning light illuminates, informing that ABS needs attention, initial tests involve checking brake fluid, admiring electrical connection, checking fuses and wiring harnesses. In the event of a persistence of these problems, professional diagnosis is advised. For wheel speed sensor replacement, the procedure entails loosening lug nuts, lifting the vehicle, disconnecting the sensor's electrical connection, removing the mounting screw, and gently pulling the sensor out, and then the reverse process while making sure that all the silver screws and lug nuts are tight.

Related Hyundai Sonata Parts

Browse by Year

2019 ABS Sensor 2018 ABS Sensor 2017 ABS Sensor 2016 ABS Sensor 2015 ABS Sensor 2014 ABS Sensor 2013 ABS Sensor 2012 ABS Sensor 2011 ABS Sensor 2010 ABS Sensor 2009 ABS Sensor 2008 ABS Sensor 2007 ABS Sensor 2006 ABS Sensor 2005 ABS Sensor 2004 ABS Sensor 2003 ABS Sensor 2002 ABS Sensor 2001 ABS Sensor 2000 ABS Sensor 1999 ABS Sensor 1998 ABS Sensor 1997 ABS Sensor 1996 ABS Sensor 1995 ABS Sensor 1994 ABS Sensor 1993 ABS Sensor 1992 ABS Sensor 1991 ABS Sensor 1990 ABS Sensor 1989 ABS Sensor 1988 ABS Sensor