×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Hyundai Parts

- Hyundai Accessories

My Garage

My Account

Cart

Genuine Hyundai Accent Battery Cable

Car Battery Cable- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

28 Battery Cables found

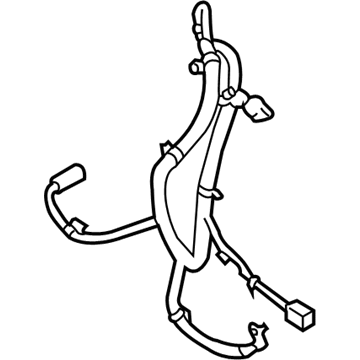

Hyundai Accent Wiring Assembly-Battery (+)

Part Number: 91850-1E012$215.01 MSRP: $302.08You Save: $87.07 (29%)Ships in 1-3 Business DaysHyundai Accent Wiring Assembly-Battery (-)

Part Number: 91860-1E011$60.11 MSRP: $84.45You Save: $24.34 (29%)Ships in 1-3 Business DaysHyundai Accent Wiring Assembly-Battery

Part Number: 91850-1R212$377.01 MSRP: $534.34You Save: $157.33 (30%)Ships in 1-3 Business DaysHyundai Accent Wiring Assembly-Battery (+)

Part Number: 91850-1E020$380.77 MSRP: $539.68You Save: $158.91 (30%)Ships in 1-3 Business DaysHyundai Accent Wiring Assembly-Battery (+)

Part Number: 91850-1E011$408.59 MSRP: $579.10You Save: $170.51 (30%)Ships in 1-3 Business DaysHyundai Accent Cable Assembly-Battery

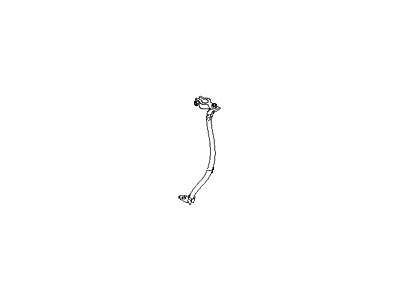

Part Number: 37210-22000$61.12 MSRP: $85.87You Save: $24.75 (29%)Ships in 1-3 Business DaysHyundai Accent Cable Assembly-Battery

Part Number: 37210-22100$61.12 MSRP: $85.87You Save: $24.75 (29%)Ships in 1-3 Business DaysHyundai Accent Cable Assembly-Battery

Part Number: 37210-22101$61.12 MSRP: $85.87You Save: $24.75 (29%)Ships in 1-3 Business DaysHyundai Accent Cable Assembly-Battery

Part Number: 37210-25100$67.10 MSRP: $94.27You Save: $27.17 (29%)Ships in 1-3 Business DaysHyundai Accent Wiring Assembly-Battery (+)

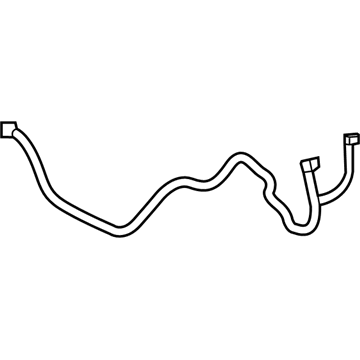

Part Number: 91850-1E023$153.66 MSRP: $215.89You Save: $62.23 (29%)Ships in 1-3 Business DaysHyundai Accent Wiring Assembly-Battery

Part Number: 91850-H9040$164.20 MSRP: $230.69You Save: $66.49 (29%)Ships in 1-3 Business DaysHyundai Accent Wiring Assembly-Battery

Part Number: 91850-H9110$256.67 MSRP: $360.61You Save: $103.94 (29%)Ships in 1-3 Business DaysHyundai Accent Wiring Assembly-Battery

Part Number: 91850-1R200$311.90 MSRP: $438.21You Save: $126.31 (29%)Ships in 1-3 Business DaysHyundai Accent Wiring Assembly-Battery

Part Number: 91850-1R204$311.90 MSRP: $438.21You Save: $126.31 (29%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 28 Results

Hyundai Accent Battery Cable

If you are looking for affordable high-quality OEM Hyundai Accent Battery Cable, then you have come to the prime place. Our website provides a large amount of genuine Hyundai Accent Battery Cable at unbeatable prices. All our parts come backed with the manufacturer's warranty.

Hyundai Accent Battery Cable Parts Questions & Experts Answers

- Q: How to inspect and replace battery cables on Hyundai Accent?A:From time to time, inspect all of the battery cables along their entire length for damage, cracked or burned insulation and corrosion because shoddy battery cable connections can cause starting problems as well as reduce engine performance. Inspect the cables' connections to the terminals for cracks, corroded wire strands and looseness. Presence of white fluffy deposits beneath insulation at the cable terminal connection indicates corrosion and need for replacement. Look at terminals for distortion, missing hardware and corrosion. When disconnecting cables always start with negative then only connect it last in an effort to prevent shorting out the battery. Disconnect old cables, ensuring that new ones are of equal diameter and length with initial one. When purchasing new ones together with others ensure you take these old ones as a guarantee that they will fully match. Red colored larger diameter positive cables have a larger diameter battery post clamp while black smaller in diameter ground cables have a slightly smaller diameter clamp for the negative post. Use a wire brush to scrape away rust and corrosion from relay or ground connection threads before applying light coating of battery terminal corrosion inhibitor or petroleum jelly that will stop future corrosions from occurring on them again.Attach the mounting nut/bolt securely so that it does not get loose after fixing the cables on relay or ground connection.Before connecting any other cable into a cell make sure it reaches battery post without stretching.Clean batteries posts thoroughly using this liquid or petroleum jelly to cut out any form of corrosion from occurring.Connect positive cable first followed by negative one.

Related Hyundai Accent Parts

Browse by Year

2022 Battery Cable 2021 Battery Cable 2020 Battery Cable 2019 Battery Cable 2018 Battery Cable 2017 Battery Cable 2016 Battery Cable 2015 Battery Cable 2014 Battery Cable 2013 Battery Cable 2012 Battery Cable 2011 Battery Cable 2010 Battery Cable 2009 Battery Cable 2008 Battery Cable 2007 Battery Cable 2006 Battery Cable 2005 Battery Cable 2004 Battery Cable 2003 Battery Cable 2002 Battery Cable 2001 Battery Cable 2000 Battery Cable 1999 Battery Cable 1998 Battery Cable 1997 Battery Cable 1996 Battery Cable 1995 Battery Cable 1994 Battery Cable