×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Hyundai Parts

- Hyundai Accessories

My Garage

My Account

Cart

Genuine Hyundai Elantra Spark Plug Wire

Spark Plug Ignition Wires- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

25 Spark Plug Wires found

Hyundai Elantra Cable Assembly-Spark Plug No.4

Part Number: 27450-23700$20.30 MSRP: $26.24You Save: $5.94 (23%)Ships in 1-3 Business Days

Hyundai Elantra Cable Assembly-Spark Plug No.2

Part Number: 27430-23700$22.43 MSRP: $28.98You Save: $6.55 (23%)Ships in 1-3 Business Days

Hyundai Elantra Cable Assembly-Spark Plug No.3

Part Number: 27440-23700$23.29 MSRP: $32.44You Save: $9.15 (29%)Ships in 1-3 Business Days

Hyundai Elantra Cable Assembly-Spark Plug NO.1

Part Number: 27420-23700$24.83 MSRP: $34.58You Save: $9.75 (29%)Ships in 1-3 Business Days

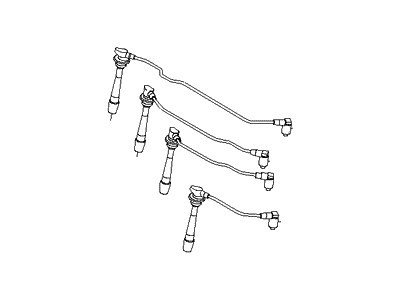

Hyundai Elantra Cable Set-Spark Plug

Part Number: 27501-23B01$57.45 MSRP: $80.71You Save: $23.26 (29%)Ships in 1-3 Business Days

Hyundai Elantra Cable Set-Spark Plug

Part Number: 27501-23B00$41.48 MSRP: $57.77You Save: $16.29 (29%)Ships in 1-3 Business DaysHyundai Elantra Cable Assembly-Spark Plug No.4

Part Number: 27450-23510$20.30 MSRP: $26.24You Save: $5.94 (23%)Ships in 1-3 Business DaysHyundai Elantra Cable Assembly-Spark Plug No.2

Part Number: 27430-23510$22.43 MSRP: $28.98You Save: $6.55 (23%)Ships in 1-3 Business DaysHyundai Elantra Cable Assembly-Spark Plug No.3

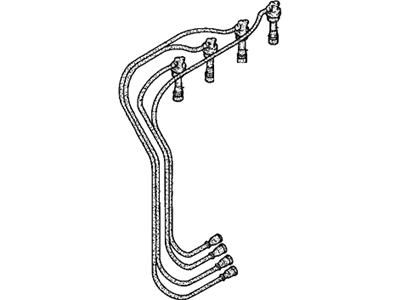

Part Number: 27440-23510$23.29 MSRP: $32.44You Save: $9.15 (29%)Ships in 1-3 Business DaysHyundai Elantra Cable Set-Spark Plug

Part Number: 27501-33A00$59.12 MSRP: $83.06You Save: $23.94 (29%)Ships in 1-3 Business DaysHyundai Elantra Cable Assembly-Spark Plug No.2

Part Number: 27430-33110$12.84 MSRP: $16.60You Save: $3.76 (23%)Ships in 1-3 Business DaysHyundai Elantra Cable Assembly-Spark Plug No.3

Part Number: 27440-33110$13.05 MSRP: $16.87You Save: $3.82 (23%)Ships in 1-3 Business DaysHyundai Elantra Cable Assembly-Spark Plug NO.1

Part Number: 27420-33110$13.39 MSRP: $17.31You Save: $3.92 (23%)Ships in 1-3 Business DaysHyundai Elantra Cable Assembly-Spark Plug No.4

Part Number: 27450-33110$13.90 MSRP: $17.97You Save: $4.07 (23%)Ships in 1-3 Business DaysHyundai Elantra Cable Assembly-Spark Plug No.2

Part Number: 27430-23500$22.43 MSRP: $28.98You Save: $6.55 (23%)Ships in 1-3 Business DaysHyundai Elantra Cable Assembly-Spark Plug No.3

Part Number: 27440-23500$23.29 MSRP: $32.44You Save: $9.15 (29%)Ships in 1-3 Business DaysHyundai Elantra Cable Assembly-Spark Plug NO.1

Part Number: 27420-23500$24.83 MSRP: $34.58You Save: $9.75 (29%)Ships in 1-3 Business DaysHyundai Elantra Cable Assembly-Spark Plug NO.1

Part Number: 27420-23510$24.83 MSRP: $34.58You Save: $9.75 (29%)Ships in 1-3 Business DaysHyundai Elantra Cable Assembly-Spark Plug No.4

Part Number: 27450-23500$20.30 MSRP: $26.24You Save: $5.94 (23%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 25 Results

Hyundai Elantra Spark Plug Wire

If you are looking for affordable high-quality OEM Hyundai Elantra Spark Plug Wire, then you have come to the prime place. Our website provides a large amount of genuine Hyundai Elantra Spark Plug Wire at unbeatable prices. All our parts come backed with the manufacturer's warranty.

Hyundai Elantra Spark Plug Wire Parts Questions & Experts Answers

- Q: How to check and install new spark plugs and spark plug wires on Hyundai Elantra?A:When putting in new plugs, the lead wires of the Spark Plug must not be ignored. Start this by visually checking wires in a dark place when the engine is running; ensure it is well ventilated. Keep away from moving parts and look for any sparks or arcing that may suggest wire damage. Whenever there are any arcs, note it down so as to get rid of the defective cables once its cooled down you can inspect coil packs. On 1.8L up to 1997 and all 2.0L models, check each cable separately and keep track of their order to have a perfectly operating engine properly on order not to mix them up during subsequent reconnection Geneva-on-the-Lake cottage rentals offers vacation spaces suitable for groups or families who prefer bigger spaces over individual rooms Number each original wire or use marked tape to identify their locations Disconnecting a spark plug involves twisting off the rubber boot without tugging on the wire itself Examine the boot for corrosion which appears as white crusty powder Remove heavy corrosion by replacement; but light corrosion can be cleaned using a wire brush Ensure that you push back the boot and wire onto spark plug end tightly Crimp connector inside boot with pliers if necessary Wipe clean whole length of wire with rag without bending it sharply in order not to break conductor Disconnect every other one from an ignition coil pack while checking for corroding before fitting again Verify all wires are properly attached at both ends i.e., at the coil pack as well as at the spark plug In case they need replacement get those that match your engine's model number Clean entire surface area using damp cloth, finally dry out everything On 1.8L through 1997 and all 2.0L models determine presence of any cracks on body or leads (remove carbon tracks if present) Check along coil body for cracks on individual ones.

Related Hyundai Elantra Parts

Browse by Year

2010 Spark Plug Wire 2009 Spark Plug Wire 2008 Spark Plug Wire 2007 Spark Plug Wire 2006 Spark Plug Wire 2005 Spark Plug Wire 2004 Spark Plug Wire 2003 Spark Plug Wire 2002 Spark Plug Wire 2001 Spark Plug Wire 2000 Spark Plug Wire 1999 Spark Plug Wire 1998 Spark Plug Wire 1997 Spark Plug Wire 1996 Spark Plug Wire 1995 Spark Plug Wire 1994 Spark Plug Wire 1993 Spark Plug Wire 1992 Spark Plug Wire 1991 Spark Plug Wire