×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Hyundai Parts

- Hyundai Accessories

My Garage

My Account

Cart

Genuine Hyundai Santa Fe Battery Cable

Car Battery Cable- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

31 Battery Cables found

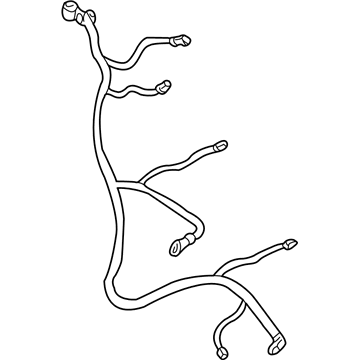

Hyundai Santa Fe Cable Assembly-Battery

Part Number: 37210-26001$195.58 MSRP: $274.79You Save: $79.21 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Wiring Assembly-Battery (+)

Part Number: 91850-2B110$481.47 MSRP: $682.39You Save: $200.92 (30%)Ships in 1-3 Business DaysHyundai Santa Fe Wiring Assembly-Battery (+)

Part Number: 91850-2B000$569.53 MSRP: $807.21You Save: $237.68 (30%)Ships in 1-3 Business DaysHyundai Santa Fe Cable Assembly-Battery

Part Number: 37210-26200$183.92 MSRP: $258.40You Save: $74.48 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Cable Assembly-Battery

Part Number: 37210-26300$195.58 MSRP: $274.79You Save: $79.21 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Cable Assembly-Battery

Part Number: 37210-26201$201.93 MSRP: $283.71You Save: $81.78 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Cable Assembly-Battery

Part Number: 37210-26000$214.74 MSRP: $301.71You Save: $86.97 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Cable Assembly-Battery

Part Number: 37210-26002$214.74 MSRP: $301.71You Save: $86.97 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Cable Assembly-Battery

Part Number: 37210-26003$214.74 MSRP: $301.71You Save: $86.97 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Cable Assembly-Battery

Part Number: 37240-26000$214.74 MSRP: $301.71You Save: $86.97 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Wiring Assembly-Battery

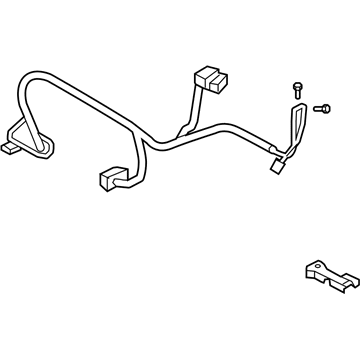

Part Number: 91850-B8413$394.95 MSRP: $559.77You Save: $164.82 (30%)Ships in 1-3 Business DaysHyundai Santa Fe Wiring Assembly-Battery (+)

Part Number: 91850-0W110$437.74 MSRP: $620.42You Save: $182.68 (30%)Ships in 1-3 Business DaysHyundai Santa Fe Wiring Assembly-Battery (+)

Part Number: 91850-2B100$569.53 MSRP: $807.21You Save: $237.68 (30%)Ships in 1-3 Business DaysHyundai Santa Fe Wiring Assembly-Battery (+)

Part Number: 91850-0W000$671.49 MSRP: $951.71You Save: $280.22 (30%)Ships in 1-3 Business DaysHyundai Santa Fe Wiring Assembly-Battery (+)

Part Number: 91850-0W100$651.35 MSRP: $923.16You Save: $271.81 (30%)Ships in 1-3 Business DaysHyundai Santa Fe Wiring Assembly-Battery

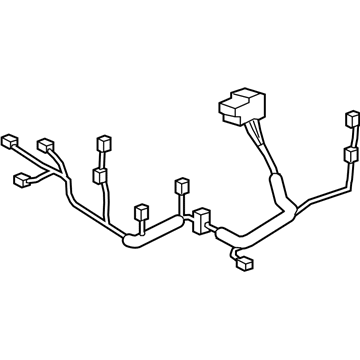

Part Number: 91850-B8410$756.87 MSRP: $1082.23You Save: $325.36 (31%)Ships in 1-3 Business DaysHyundai Santa Fe Wiring Assembly-Battery

Part Number: 91850-B8411$756.87 MSRP: $1082.23You Save: $325.36 (31%)Ships in 1-3 Business DaysHyundai Santa Fe Wiring Assembly-Battery

Part Number: 91850-B8412$756.87 MSRP: $1082.23You Save: $325.36 (31%)Ships in 1-3 Business DaysHyundai Santa Fe Wiring Assembly-Battery (-)

Part Number: 91860-0W000$82.00 MSRP: $115.21You Save: $33.21 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Wiring Assembly-Battery (-)

Part Number: 91860-2B000$82.00 MSRP: $115.21You Save: $33.21 (29%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 31 Results

Hyundai Santa Fe Battery Cable

If you are looking for affordable high-quality OEM Hyundai Santa Fe Battery Cable, then you have come to the prime place. Our website provides a large amount of genuine Hyundai Santa Fe Battery Cable at unbeatable prices. All our parts come backed with the manufacturer's warranty.

Hyundai Santa Fe Battery Cable Parts Questions & Experts Answers

- Q: How to inspect and replace battery cables on Hyundai Santa Fe?A:After a certain period, examine all of the battery cables from end to end for signs of damage, cracked or burnt insulation or corrosion. Poor battery cable connections may result in starting difficulties as well as reduce engine performances. Check the cable-to-terminal connections at the end of the wires for splits on it, frayed wire ends and corrosion. Seeing white fluffy substance beneath the insulation on the cable terminal connector implies corrosion has taken place in these areas and therefore cable ought to be replaced. The terminals should also be inspected for defects like deformation, no mounting bolts and instead corrosion. Never forget to remove negative lines first while loosening often when you are separating such cables this could cause crashing auxilary bar with your tool when you're trying loosening them because it is possible that you might mistakenly short circuit your battery with a tool used to loosen up the clamps if it is not done so properly always separate lines through removing minus one before positive one even though they will be replacing only a plus line.Disconnect old wires from batteries then find each one from which they are connected and release them off from solenoid starting system and ground part just opposite each other. Observe how every line is laid out before connecting them back properly. Always carry along both old cables if either ones want replacement.The identification of these cables cannot be difficult.Cleaning rust or corrosion should be done by use of brush that has wire threads; apply light layers of jelly or anti-corrosion on terminals.Apply enough force to tighten nuts/bolts that hold cable onto ground connection/ solenoid thread.Without any stretching connect new wire very easily into post at topmost corner that connects with electric reservoir and never stretch.Connect red positive first then black negative suggested correct order when hooking up new charger line respectively.

Related Hyundai Santa Fe Parts

Browse by Year

2023 Battery Cable 2022 Battery Cable 2021 Battery Cable 2020 Battery Cable 2019 Battery Cable 2018 Battery Cable 2017 Battery Cable 2016 Battery Cable 2015 Battery Cable 2014 Battery Cable 2013 Battery Cable 2012 Battery Cable 2011 Battery Cable 2010 Battery Cable 2009 Battery Cable 2008 Battery Cable 2007 Battery Cable 2006 Battery Cable 2005 Battery Cable 2004 Battery Cable 2003 Battery Cable 2002 Battery Cable 2001 Battery Cable 2000 Battery Cable