×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Hyundai Parts

- Hyundai Accessories

My Garage

My Account

Cart

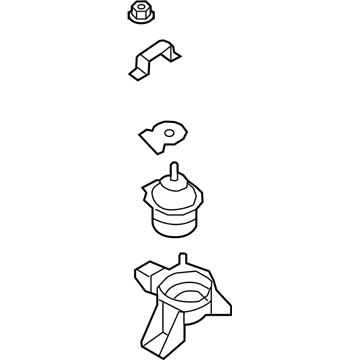

Genuine Hyundai Sonata Engine Mount

Engine Motor Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

76 Engine Mounts found

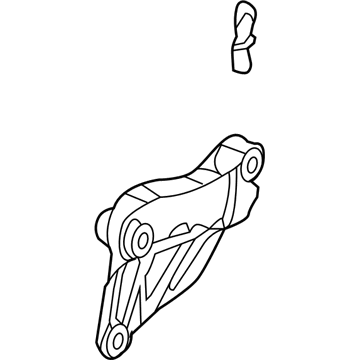

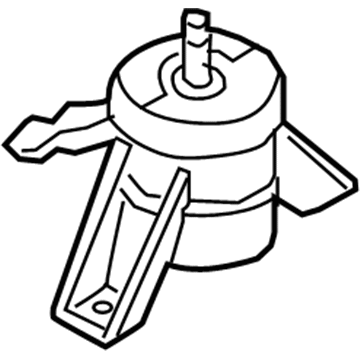

Hyundai Sonata Engine Mounting Bracket Assembly

Part Number: 21810-2T000$314.86 MSRP: $442.37You Save: $127.51 (29%)Ships in 1-3 Business Days

Hyundai Sonata Engine Mounting Bracket Assembly

Part Number: 21810-3Q000$286.24 MSRP: $402.16You Save: $115.92 (29%)Ships in 1-3 Business Days

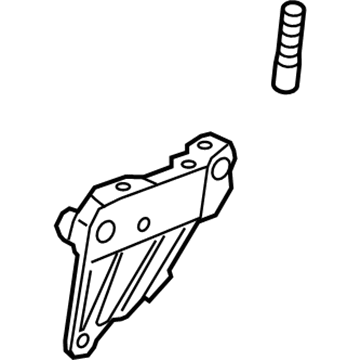

Hyundai Sonata Engine Support Bracket Assembly

Part Number: 21670-2B210$78.44 MSRP: $110.21You Save: $31.77 (29%)Ships in 1-3 Business Days

Hyundai Sonata Engine Mounting Bracket Assembly

Part Number: 21810-3K850$292.63 MSRP: $411.13You Save: $118.50 (29%)Ships in 1-3 Business Days

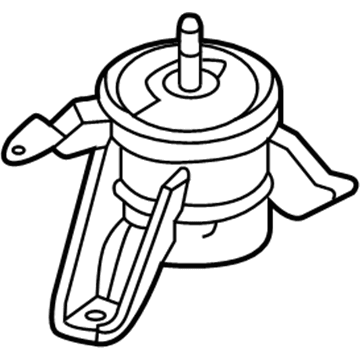

Hyundai Sonata Engine Mounting Bracket Assembly

Part Number: 21810-3L300$388.60 MSRP: $550.77You Save: $162.17 (30%)Ships in 1-3 Business Days

Hyundai Sonata Engine Mounting Bracket Assembly

Part Number: 21810-C2220$286.24 MSRP: $402.16You Save: $115.92 (29%)Ships in 1-3 Business Days

Hyundai Sonata Engine Mounting Bracket Assembly

Part Number: 21810-3K400$388.60 MSRP: $550.77You Save: $162.17 (30%)Ships in 1-3 Business Days

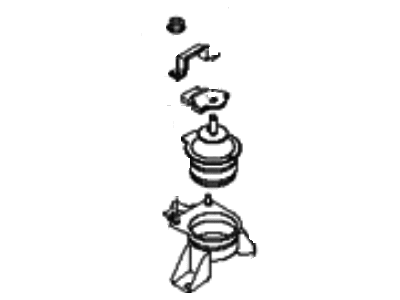

Hyundai Sonata Engine Support Bracket Assembly

Part Number: 21670-2GGB0$100.74 MSRP: $141.53You Save: $40.79 (29%)Ships in 1-3 Business DaysHyundai Sonata Engine Mounting Bracket Assembly

Part Number: 21810-C1020$286.24 MSRP: $402.16You Save: $115.92 (29%)Ships in 1-3 Business DaysHyundai Sonata Engine Support Bracket Assembly

Part Number: 21670-2GGB1$100.74 MSRP: $141.53You Save: $40.79 (29%)Ships in 1-3 Business DaysHyundai Sonata Engine Mounting Bracket Assembly

Part Number: 21810-C1320$286.24 MSRP: $402.16You Save: $115.92 (29%)Ships in 1-3 Business DaysHyundai Sonata Engine Mounting Bracket Assembly

Part Number: 21810-D4020$286.24 MSRP: $402.16You Save: $115.92 (29%)Ships in 1-3 Business DaysHyundai Sonata Engine Mounting Bracket Assembly

Part Number: 21810-3L500$292.63 MSRP: $411.13You Save: $118.50 (29%)Ships in 1-3 Business DaysHyundai Sonata Engine Mounting Bracket Assembly

Part Number: 21810-3K000$350.28 MSRP: $496.45You Save: $146.17 (30%)Ships in 1-3 Business DaysHyundai Sonata Engine Mounting Bracket Assembly

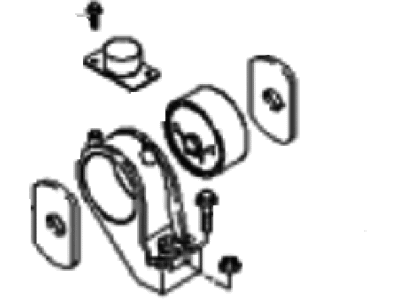

Part Number: 21810-38120$342.77 MSRP: $485.81You Save: $143.04 (30%)Ships in 1-3 Business DaysHyundai Sonata Engine Mounting Support Bracket

Part Number: 21825-C1000$133.39 MSRP: $187.40You Save: $54.01 (29%)Ships in 1-3 Business DaysHyundai Sonata Engine Support Bracket Assembly

Part Number: 21670-2G000$64.13 MSRP: $90.10You Save: $25.97 (29%)Ships in 1-3 Business DaysHyundai Sonata Engine Mounting Bracket Assembly

Part Number: 21810-3Q850$286.24 MSRP: $402.16You Save: $115.92 (29%)Ships in 1-3 Business DaysHyundai Sonata Engine Mounting Bracket Assembly

Part Number: 21810-C1120$286.24 MSRP: $402.16You Save: $115.92 (29%)Ships in 1-3 Business DaysHyundai Sonata Engine Mounting Bracket Assembly

Part Number: 21810-C2320$271.93 MSRP: $382.05You Save: $110.12 (29%)Ships in 1-3 Business Days

| Page 1 of 4 |Next >

1-20 of 76 Results

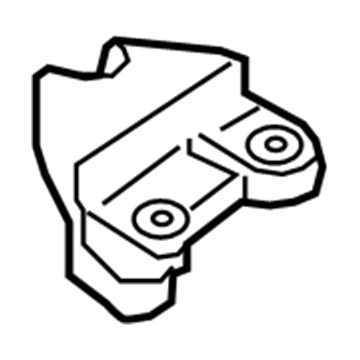

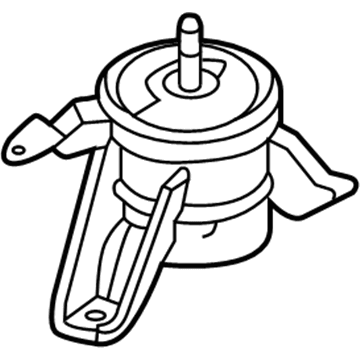

Hyundai Sonata Engine Mount

If you are looking for affordable high-quality OEM Hyundai Sonata Engine Mount, then you have come to the prime place. Our website provides a large amount of genuine Hyundai Sonata Engine Mount at unbeatable prices. All our parts come backed with the manufacturer's warranty.

Hyundai Sonata Engine Mount Parts Questions & Experts Answers

- Q: What actions are necessary if the engine mount is broken or deteriorated on Hyundai Sonata?A:Powertrain mounts are very durable and hardly ever anything is wrong with them but when you find a powertrain mount to be broken or old, it is much appreciated to fix it since additional force that is put onto other auto components can cause more wear and tear of the auto's driveshaft. During the check, the engine or transaxle should slightly be lifted off of the mounts to relieve the load. Start by lifting up the car and supporting it with jack-stands; if the vehicle has an engine splash shield, it should be removed and a jack placed under the engine oil pan but with a large piece of wood in between the jack and the oil pan. Gently lift the engine just enough to relieve the weight off the mounts, but make sure the wood block is not under the oil drain plug. Visually check for cracks, hard rubber and disconnection of the bushing in the middle of the mount, and shake the mount brackets relative to the engine or frame using a screwdriver or prybar. If any movement is observed, lower the engine and re-tighten the mount's nuts and bolts. All engine mounts are replaced similarly; first, to support the engine's weight use the jack, and then remove all the pressure off of the mount in question. Unscrew the bolts situated at both ends of the mount and then proceed to uninstall the faulty mount; afterward, put in the new mount and fasten all bolts in place.

Related Hyundai Sonata Parts

Browse by Year

2023 Engine Mount 2022 Engine Mount 2021 Engine Mount 2020 Engine Mount 2019 Engine Mount 2018 Engine Mount 2017 Engine Mount 2016 Engine Mount 2015 Engine Mount 2014 Engine Mount 2013 Engine Mount 2012 Engine Mount 2011 Engine Mount 2010 Engine Mount 2009 Engine Mount 2008 Engine Mount 2007 Engine Mount 2006 Engine Mount 2005 Engine Mount 2004 Engine Mount 2003 Engine Mount 2002 Engine Mount 2001 Engine Mount 2000 Engine Mount 1999 Engine Mount 1998 Engine Mount 1997 Engine Mount 1996 Engine Mount 1995 Engine Mount 1994 Engine Mount 1993 Engine Mount 1992 Engine Mount 1991 Engine Mount 1990 Engine Mount 1989 Engine Mount 1988 Engine Mount