×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Hyundai Parts

- Hyundai Accessories

My Garage

My Account

Cart

Genuine Hyundai Accent Sway Bar Kit

Stabilizer Sway Bar Set- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Sway Bar Kits found

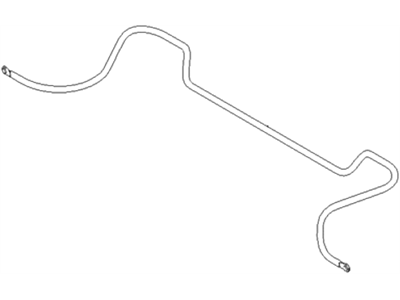

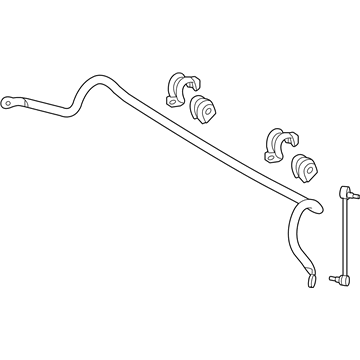

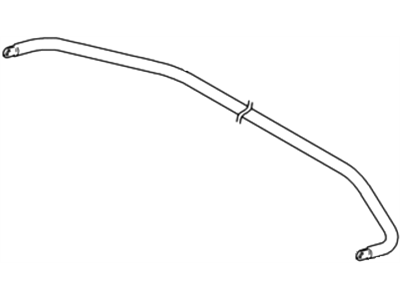

Hyundai Accent Bar-Rear Stabilizer

Part Number: 55512-25000$115.39 MSRP: $162.11You Save: $46.72 (29%)Ships in 1-3 Business DaysHyundai Accent Bar Assembly-Front Stabilizer

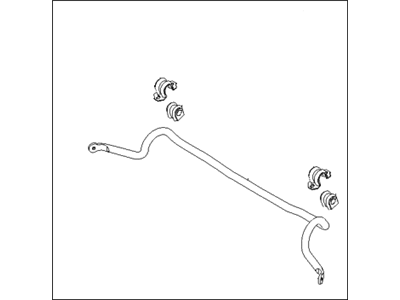

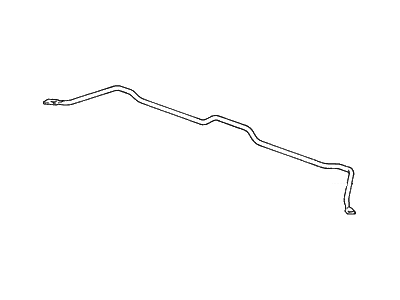

Part Number: 54801-1G000$205.55 MSRP: $288.79You Save: $83.24 (29%)Ships in 1-3 Business DaysHyundai Accent Bar Assembly-Front Stabilizer

Part Number: 54801-1G100$244.46 MSRP: $343.45You Save: $98.99 (29%)Ships in 1-3 Business DaysHyundai Accent Bar-Rear Stabilizer

Part Number: 55512-22000$104.86 MSRP: $147.32You Save: $42.46 (29%)Ships in 1-3 Business DaysHyundai Accent Bar Assembly-Front Stabilizer

Part Number: 54810-1R100$221.33 MSRP: $310.97You Save: $89.64 (29%)Ships in 1-3 Business DaysHyundai Accent Bar Assembly-Front Stabilizer

Part Number: 54810-H9000$141.71 MSRP: $199.10You Save: $57.39 (29%)Ships in 1-3 Business Days

Hyundai Accent Sway Bar Kit

If you are looking for affordable high-quality OEM Hyundai Accent Sway Bar Kit, then you have come to the prime place. Our website provides a large amount of genuine Hyundai Accent Sway Bar Kit at unbeatable prices. All our parts come backed with the manufacturer's warranty.

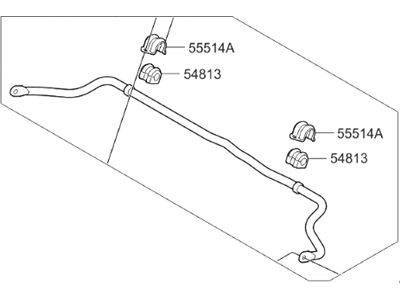

Hyundai Accent Sway Bar Kit Parts Questions & Experts Answers

- Q: How to remove and install the rear axle assembly and Sway Bar Kit on Hyundai Accent?A:Remove rear axle assembly from 1994 and earlier model. Apply white paint or a scribe to match marks on the Sway Bar Kit that would align it with the punch marks on the sway bar brackets. This will ensure proper alignment of the Sway Bar Kit splines during installation. Pull Trailing Arms far apart enough to allow removal of Sway Bar Kit from splines. Examine Sway Bar Kit for cracks, distortion, or corrosion. Put in new Sway Bar Kit and any worn out, damaged, or deteriorated parts if needed. Install rear axle assembly. For 1995 through 2005 models, loosen and remove the sway bar link bolt and locknut, removing the link cup washers, bushings, and sleeve; also take note of what their placement was before removing them. Remove the car's frame-mounted clamps for mounting the support rod on it. Check if there are any cracks, distortions, or signs of corrosion in your support rod after going through these processes twice in a year then version is likely not good enough since you need one annually! If necessary, install a new Sway Bar Kit as well as any worn out or broken parts which could be detrimental to its normal functioning process too! First things first when installing your Sway Bar Kit is to get those slits facing towards the body mounting surface where they should be located within before doing anything else at all even though this may seem complicated but once we start getting used to such kind of activities which are quite similar among many other types of parts made up of metal then everything becomes very easy; especially because during manufacturing people usually keep everything standardized so that everyone has no doubts about how exactly he/she has done his/her job right from beginning till end without missing any single step throughout the whole process. The process requires some tools including wrenches (gear wrench especially), standard socket sets like Allen keys, impact drivers besides various other things among them such as hammer etc. Make sure all bolts are tight before turning on the engine again; otherwise, you would just be wasting time trying to fix those loose joints of yours by tightening them up which will only result in more frustration than anything else around here even after finishing assembling back everything together, one should not forget checking if there are any signs of damages occurring on it again if necessary! Position sway bar bushings with slits facing the body mounting surface. Find Sway Bar Kit at frame and place clamps over bushing but do not fully tighten bolt at this point. Place a cup washer and bushing onto the link bolt and then slide the bolt into the Sway Bar Kit end hole. Take notes from your previous disassembly regarding installing a bushing, sleeve, bushing, cup washer, and locknut in sequence on link bolt. Turn in lock nut until about an inch of thread protrudes beyond it. Tighten clamp bolts to torque strength.

Related Hyundai Accent Parts

Browse by Year

2022 Sway Bar Kit 2021 Sway Bar Kit 2020 Sway Bar Kit 2019 Sway Bar Kit 2018 Sway Bar Kit 2017 Sway Bar Kit 2016 Sway Bar Kit 2015 Sway Bar Kit 2014 Sway Bar Kit 2013 Sway Bar Kit 2012 Sway Bar Kit 2011 Sway Bar Kit 2010 Sway Bar Kit 2009 Sway Bar Kit 2008 Sway Bar Kit 2007 Sway Bar Kit 2006 Sway Bar Kit 2005 Sway Bar Kit 2004 Sway Bar Kit 2003 Sway Bar Kit 2002 Sway Bar Kit 2001 Sway Bar Kit 2000 Sway Bar Kit 1999 Sway Bar Kit 1998 Sway Bar Kit 1997 Sway Bar Kit 1996 Sway Bar Kit 1995 Sway Bar Kit 1994 Sway Bar Kit