×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Hyundai Parts

- Hyundai Accessories

My Garage

My Account

Cart

Genuine Hyundai Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

221 Cylinder Heads found

Hyundai Head Assembly-Cylinder

Part Number: 22100-23780$881.39 MSRP: $1260.27You Save: $378.88 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Head

- Replaces: 22100-23630

Hyundai Head Assembly-Cylinder

Part Number: 22100-2B725$706.62 MSRP: $1010.39You Save: $303.77 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Head

- Replaces: 22100-2B720

- Product Specifications

- Other Name: Cylinder Head

Hyundai Head Assembly-Cylinder

Part Number: 22100-23730$718.99 MSRP: $1028.06You Save: $309.07 (31%)Ships in 1-3 Business DaysProduct Specifications- Replaces: 22100-23620

Hyundai Head Sub Assembly-Cylinder, RH

Part Number: 517R5-3CA00$1266.95 MSRP: $1811.58You Save: $544.63 (31%)Product Specifications- Other Name: Cylinder Head

- Position: Passenger Side

Hyundai Head Assembly-Cylinder

Part Number: 22100-2E001$574.83 MSRP: $814.71You Save: $239.88 (30%)Ships in 1-3 Business DaysHyundai Head Assembly-Cylinder

Part Number: 22100-2G561$690.73 MSRP: $987.66You Save: $296.93 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Head

Hyundai Head Assembly-Cylinder

Part Number: 22100-2E085$680.93 MSRP: $973.65You Save: $292.72 (31%)Ships in 1-3 Business DaysProduct Specifications- Replaced by: 70ZP5-2EX00

Hyundai Head Sub Assembly-Cylinder, LH

Part Number: 516R5-3CA00$1599.05 MSRP: $2286.45You Save: $687.40 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Head

- Position: Driver Side

Hyundai Head Assembly-Cylinder

Part Number: 72RU5-2GF00$951.28 MSRP: $1360.21You Save: $408.93 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Head

- Replaces: 22100-2G750, 591TH-2GA04-D, 591TH-2GA04

Hyundai Head Assembly-Cylinder

Part Number: 22100-22021$594.34 MSRP: $842.37You Save: $248.03 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Head

- Replaces: 22100-22030

Hyundai Head Assembly-Cylinder

Part Number: 22100-2G460$693.16 MSRP: $991.13You Save: $297.97 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Head

- Replaced by: 38RY4-2GF00

Hyundai Head Assembly-Cylinder

Part Number: 22100-2E002$574.83 MSRP: $814.71You Save: $239.88 (30%)Ships in 1-3 Business DaysProduct Specifications- Replaces: 22110-2E002

Hyundai Head Assembly-Cylinder

Part Number: 22100-2B720$706.62 MSRP: $1010.39You Save: $303.77 (31%)Ships in 1-2 Business DaysProduct Specifications- Replaced by: 22100-2B725

Hyundai Head Sub Assembly-Cylinder, RH

Part Number: 22110-3CGB1$1428.71 MSRP: $2042.89You Save: $614.18 (31%)Ships in 1-3 Business DaysProduct Specifications- Position: Passenger Side

Product Specifications

Product Specifications- Other Name: Cylinder Head

- Replaces: 22100-26150

- Product Specifications

- Other Name: Cylinder Head

Hyundai Head Assembly-Cylinder

Part Number: 22100-26850$806.26 MSRP: $1152.85You Save: $346.59 (31%)Product Specifications- Other Name: Cylinder Head

- Replaces: 22100-26890

| Page 1 of 12 |Next >

1-20 of 221 Results

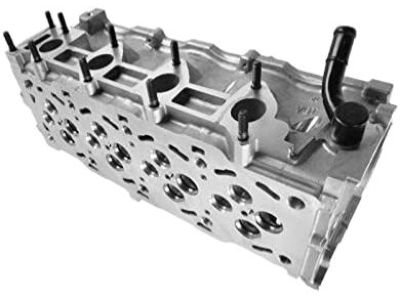

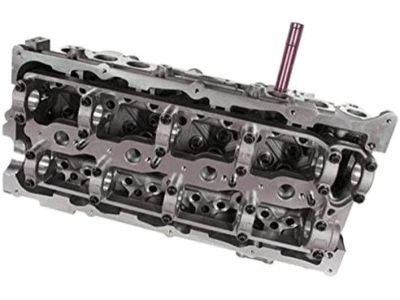

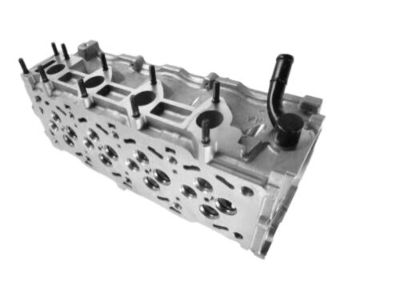

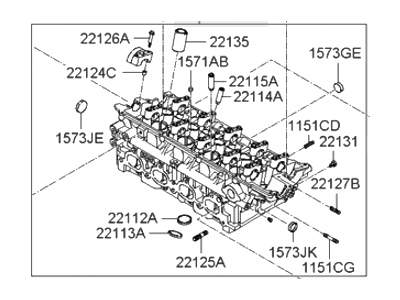

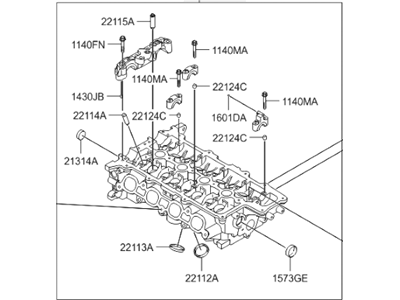

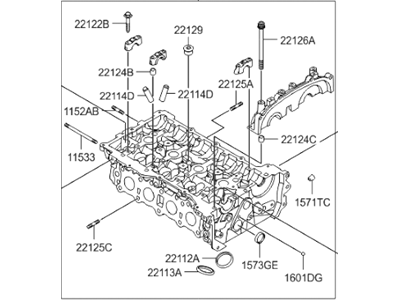

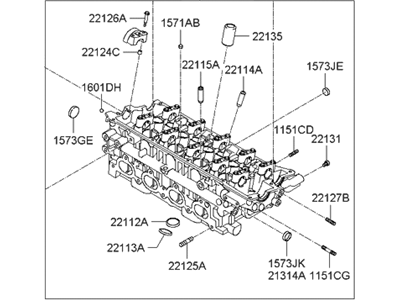

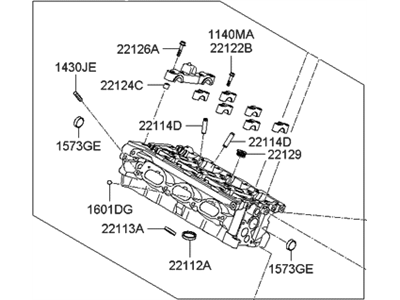

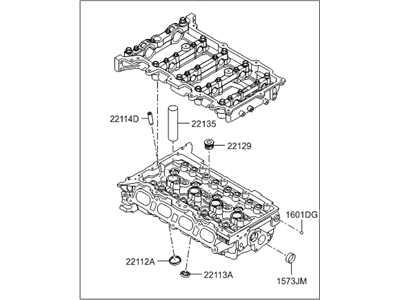

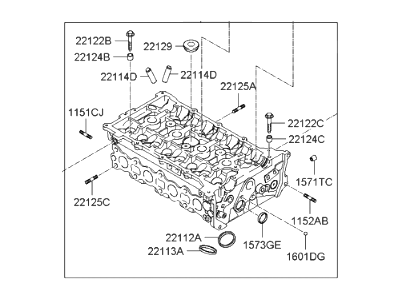

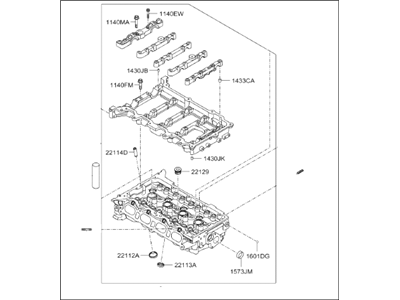

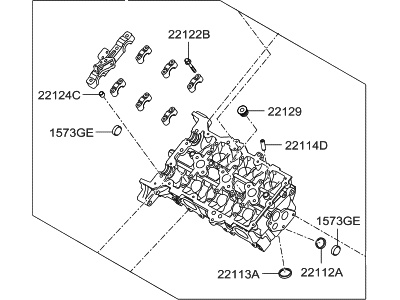

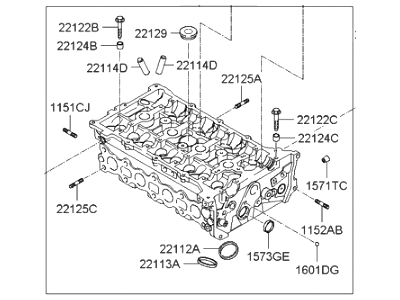

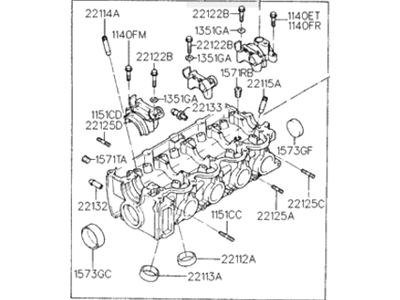

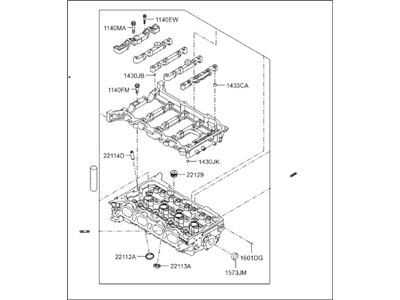

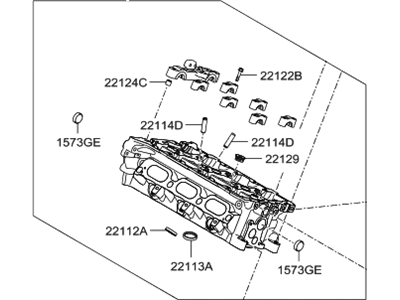

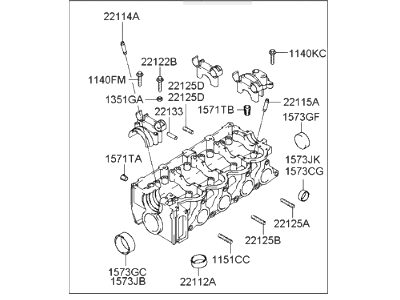

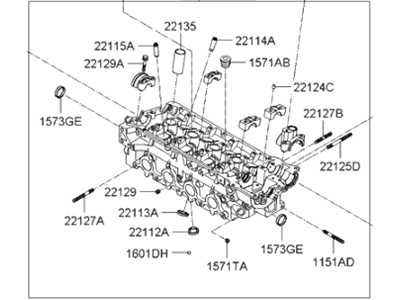

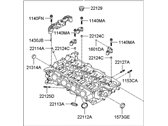

About Hyundai Cylinder Head

There is an important part in the mechanics named the cylinder head. The location of the cylinder head is on the top of the engine block. Along with the head gasket, there is a seal over the cylinder, allowing the pistons to function and protects the engine's delicate components. It is necessary for the engine to work with vacuum condition. So if the cylinder head leaks, cracks, or sustains other damage, it can affect the engine in a negative way. Don't wait too late until the engine needs to be changed since it gets hurt by cylinder head too much. If you find anything wrong with the cylinder head, you need to stop driving immediately and check it if the replacement is necessary. Once you decide to change, we are glad to offer you all Hyundai genuine OEM cylinder head with a discounted price.

Hyundai Cylinder Head Parts Questions & Experts Answers

- Q: Is it more practical and economical for the home mechanic to purchase a replacement cylinder head rather than disassembling, inspecting, and reconditioning the original on Hyundai Elantra?A:New and rebuilt cylinder heads are commonly available for most engines at dealerships and auto parts stores. Since specialized tools are necessary for disassembly and inspection procedures, and replacement parts may not always be readily available, it can be more practical and economical for the home mechanic to purchase a replacement head instead of disassembling, inspecting, and reconditioning the original. For 2011 and later 1.8L engines and 2014 through 2018 2.0L GD engines, both camshafts ride in a cam carrier bolted to the top of the cylinder head. Disassembly involves removing the intake and exhaust valves along with related parts. Before removing the valves, label and store them with their components to keep them separate for reinstallation. Use a spring compressor to compress the springs on the first valve and remove the keepers, then carefully release the compressor and take out the retainer, spring, and spring seat if used. Pull the valve out of the head and remove the oil seal from the guide; if the valve binds, push it back and deburr the area around the keeper groove. Repeat this for the remaining valves, ensuring all parts for each valve are kept together for reinstallation. After removing and organizing the valves and components, thoroughly clean and inspect the heads, completing engine disassembly procedures if a complete overhaul is being done before starting the cleaning and inspection process.

- Q: How to remove, inspect, and install the cylinder head on Hyundai Accent?A:Before you tackle the cylinder head you should relieve the fuel system pressure then disconnect the connection from the negative terminal of the battery and should drain the engine coolant. If desired the intake manifold can be left in but perform all the necessary steps to remove it. Remove coolant hoses from the cylinder head as to detach the timing chain and the camshaft sprockets, and finally lift the car on jack stands to remove the exhaust manifold. Remove the cylinder head electrical connectors by simply labeling and unplugging them off, next are the Oil Control Valves and both Camshaft Position sensors as well as the fuel injector and rail assembly. Unfasten the cylinder head bolts with a turning angle of 1/4-turn increments so that they can be easily remove without the use of tools, always untighten in an opposite sequence of the tightening pattern so that the warping or cracking of the cylinder head is avoided. With help, ease the cylinder head off the engine block: they may need a nudge, and strip any other external parts to clean them to the best of your ability. Each head's gasket surfaces are vertically checked, a feeler gauge is inserted to gauge the clearance; if beyond standard, resurfacing or replacement is done. Be sure to check around the valve seats and the seat inserts for cracks and signs of coolant leakage. Ensure the surfaces of the cylinder head to be mated are clean by using the gasket scraper and brake system cleaner, and to prevent entry of debris you stuff the cylinders with clean shop rags. Look for broken edges, missing scales or deep ruptures in the areas that are going to mate, with a file for slight damage and with machining in case the damage if severe. Stake the threads in the cylinder head bolt holes with a tap and blow clean with the compressed air. Using a smooth wire status, clean the threads of each bolt and replace any type of bolt seen to be bad. Replace the removed components in the cylinder head, put a generous amount of liquid gasket on the front corner edges of the gasket, then properly orient the new gasket, and place it firmly over the dowel pins. Place the cylinder head on the block such that the gasket is still in position; coat the threads and head of the bolts with clean engine oil, install new head bolts and washers and bring the bolts just snug with your fingers. The user is to proceed as instructed below to further tighten the bolts to the right torque with another additional of 90 degree. If new bolts/fasteners are used, it should adhere to the recommended torque sequence. The rest of the installation is the reversal of the procedure of removal, and after replacing the engine oil and filter, filling up the cooling system, start the engine and look for any signs of leakage.

- Q: How to remove and insatall cylinder heads on V6 Hyundai Sonata?A:The details of the removal where that for 1999-2005, one has to relieve the fuel system pressure and then join the negative cable of the battery. Dump the coolant and take off the upper hose to the radiator, next the upper and lower intake manifolds, and at least the exhaust manifold(s), although you may wish to leave these bolted to the cylinder heads. Remove the timing belt from the camshaft sprocket(s), spark plug wires, and all the other sensors and hoses which are out of the way of the removal process. Thus, on the vehicles produced after 2006, pull the engine out along with the installation on the engine stand, then remove the intake and exhaust manifold and the camshafts. In all models, turn the cylinder head bolts clockwise till they can be turned anticlockwise by hand, then remove the cylinder head from the engine block, gently using a wooden wedge and hammer if possible. Run a precision straight edge and feeler gauge over the gasket surfaces of each head and examine for cracks & recouse for coolant leakage. Before joining of the cylinder heads and block, the adjacent surfaces should be clean with gasket scraper and brake cleaner also the cylinders should be stuffed with rags to avoid dropping of some particles. Tighten a bolt to way-point torque then loosen to half way and go through the cycle two more times.Inspected the mating surfaces in the cylinder head and block for damages and chased the threads of the bolt holes with a tap and blew out the debris using compressed air for each way. When reassembling the head for 2.5L or 2.7L engines, clean the bolts with a vise, while for a 3.3L V6 engine, change all head bolts. Install new gaskets over the dowel pins in the block while aligning them and apply the RTV sealant. Place the head gently on the block then apply fresh engine oil on the bolt thread and v(undersides) then put and tight the bolts as per the sequence advised. The following installation steps should now be completed in reverse order of the ones listed above: Replace the top of the transmission pan; fill the cooling system; change the motor oil and filter; start the engine; check the cooling system for leaks.

Related Hyundai Parts

Browse by Model

Accent Cylinder Head Azera Cylinder Head Elantra Cylinder Head Elantra GT Cylinder Head Elantra N Cylinder Head Elantra Touring Cylinder Head Entourage Cylinder Head Equus Cylinder Head Excel Cylinder Head Genesis Coupe Cylinder Head Genesis Cylinder Head Genesis G70 Cylinder Head Genesis G80 Cylinder Head Genesis G90 Cylinder Head Genesis GV70 Cylinder Head Genesis GV80 Cylinder Head Ioniq Cylinder Head Kona Cylinder Head Kona N Cylinder Head Palisade Cylinder Head Santa Cruz Cylinder Head Santa Fe Cylinder Head Santa Fe Hybrid Cylinder Head Santa Fe Sport Cylinder Head Santa Fe XL Cylinder Head Scoupe Cylinder Head Sonata Cylinder Head Sonata Hybrid Cylinder Head Tiburon Cylinder Head Tucson Cylinder Head Veloster Cylinder Head Veloster N Cylinder Head Venue Cylinder Head Veracruz Cylinder Head XG300 Cylinder Head XG350 Cylinder Head