×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Hyundai Parts

- Hyundai Accessories

My Garage

My Account

Cart

Genuine Hyundai Santa Fe Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Brake Boosters found

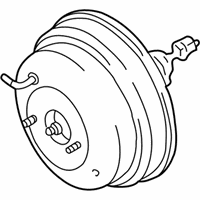

Hyundai Santa Fe Booster Assembly-Brake

Part Number: 58610-26051$1115.58 MSRP: $1595.15You Save: $479.57 (31%)Ships in 1-3 Business DaysHyundai Santa Fe Booster Assembly-Brake

Part Number: 59110-2B000$548.57 MSRP: $777.50You Save: $228.93 (30%)Ships in 1-3 Business DaysHyundai Santa Fe Booster Assembly-Brake

Part Number: 59110-2W300$846.87 MSRP: $1210.92You Save: $364.05 (31%)Ships in 1-3 Business DaysHyundai Santa Fe Booster Assembly-Brake

Part Number: 59110-2W330$536.52 MSRP: $760.42You Save: $223.90 (30%)Ships in 1-3 Business DaysHyundai Santa Fe Booster Assembly-Brake

Part Number: 58610-26000$1055.41 MSRP: $1509.11You Save: $453.70 (31%)Ships in 1-3 Business DaysHyundai Santa Fe Booster Assembly-Brake

Part Number: 59110-R5500$344.98 MSRP: $488.95You Save: $143.97 (30%)Ships in 1-3 Business DaysHyundai Santa Fe Booster Assembly-Brake

Part Number: 59110-S2000$515.91 MSRP: $731.21You Save: $215.30 (30%)Ships in 1-3 Business DaysHyundai Santa Fe Booster Assembly-Brake

Part Number: 59110-1U000$570.68 MSRP: $808.84You Save: $238.16 (30%)Ships in 1-3 Business Days

Hyundai Santa Fe Brake Booster

If you are looking for affordable high-quality OEM Hyundai Santa Fe Brake Booster, then you have come to the prime place. Our website provides a large amount of genuine Hyundai Santa Fe Brake Booster at unbeatable prices. All our parts come backed with the manufacturer's warranty.

Hyundai Santa Fe Brake Booster Parts Questions & Experts Answers

- Q: How to operate checks, airtightness checks, remove, and insatall a power brake booster on Hyundai Santa Fe?A:To carry out an operating check, bring the Brake Pedal down several times with the engine off to show that the reserve pedal distance does not change, then with the engine on check if the pedal goes down slightly. For airtightness check, switch on the engine for 1 or 2min, then switched off the engine and depress the brake pedal gently few times, if the pedal pressure is less with each depression, it indicate that the hydraulic booster is airtight. Set the brake pedal while the engine is running and shutdown the engine while the brake pedal remains depressed; when the reserve has been held for at least 30seconds there will be no reduction in the reserve travel of the pedal and hence the booster proved airtight. If the power brake booster units are removed do not disassemble them for they are sensitive and always use real tools, instead, get new or rebuilt ones. Base your procedure with the Brake Master Cylinder's removal and some models may require the removal of the Brake Lines crossing across in front of the MC. Slowly unplug the vacuum hose on the brake booster and unscrewing the brake pedal return spring on the top of the brake pedal as well as the clip and clevis pin. Secondly, to do that, unbolt the four machine screws on the brake booster to the fire wall and then pull the booster out, towards the rear of the vehicle until the studs come off the holes. For installation, this should be done in the reverse of the mentioned removal process and make sure that the booster mounting nuts are tightened to the recommended torque. It could also be used after fitting the master cylinder and brake hoses where one has to set the brake pedal height and freeplay together with bleeding the system depending on the situation.

Related Hyundai Santa Fe Parts

Browse by Year

2023 Brake Booster 2022 Brake Booster 2021 Brake Booster 2020 Brake Booster 2019 Brake Booster 2018 Brake Booster 2017 Brake Booster 2016 Brake Booster 2015 Brake Booster 2014 Brake Booster 2013 Brake Booster 2012 Brake Booster 2011 Brake Booster 2010 Brake Booster 2009 Brake Booster 2008 Brake Booster 2007 Brake Booster 2006 Brake Booster 2005 Brake Booster 2004 Brake Booster 2003 Brake Booster 2002 Brake Booster 2001 Brake Booster 2000 Brake Booster