×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Hyundai Parts

- Hyundai Accessories

My Garage

My Account

Cart

Genuine Hyundai Santa Fe Crankshaft Seal

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

29 Crankshaft Seals found

Hyundai Santa Fe Seal-Oil

Part Number: 21421-2G100$20.78 MSRP: $26.85You Save: $6.07 (23%)Ships in 1-2 Business Days

Hyundai Santa Fe Seal-Oil

Part Number: 21421-25002$20.06 MSRP: $25.92You Save: $5.86 (23%)Ships in 1-3 Business Days

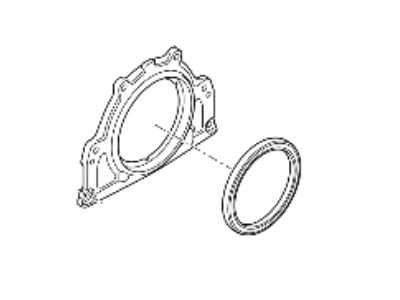

Hyundai Santa Fe Seal-Oil Rear

Part Number: 21443-2G000$28.53 MSRP: $39.74You Save: $11.21 (29%)Ships in 1-2 Business Days

Hyundai Santa Fe Seal-Oil

Part Number: 21352-3C700$27.53 MSRP: $38.34You Save: $10.81 (29%)Ships in 1-3 Business Days

Hyundai Santa Fe Seal-Oil Rear

Part Number: 21443-25000$28.53 MSRP: $39.74You Save: $11.21 (29%)Ships in 1-3 Business Days

Hyundai Santa Fe Seal-Oil Rear

Part Number: 21443-2A100$81.08 MSRP: $113.92You Save: $32.84 (29%)Ships in 1-3 Business Days

Hyundai Santa Fe Seal-Oil

Part Number: 21352-3C600$26.56 MSRP: $37.00You Save: $10.44 (29%)Ships in 1-3 Business Days

Hyundai Santa Fe Seal-Oil Rear

Part Number: 21443-3C700$49.60 MSRP: $69.08You Save: $19.48 (29%)Ships in 1-3 Business Days

Hyundai Santa Fe Seal-Oil

Part Number: 21421-33134$8.46 MSRP: $10.94You Save: $2.48 (23%)Ships in 1-3 Business Days

Hyundai Santa Fe Seal-Oil Rear

Part Number: 21443-35510$81.08 MSRP: $113.92You Save: $32.84 (29%)Ships in 1-3 Business Days

Hyundai Santa Fe Seal-Oil

Part Number: 21352-3C500$27.53 MSRP: $38.34You Save: $10.81 (29%)Ships in 1-3 Business Days

Hyundai Santa Fe Seal-Oil

Part Number: 21421-35500$13.72 MSRP: $17.73You Save: $4.01 (23%)Ships in 1-3 Business DaysHyundai Santa Fe Case Assembly-Oil Seal

Part Number: 21130-3C151$63.43 MSRP: $89.11You Save: $25.68 (29%)Ships in 1-2 Business DaysHyundai Santa Fe Seal-Oil

Part Number: 21421-33114$23.95 MSRP: $33.35You Save: $9.40 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Seal-Oil Rear

Part Number: 21443-3E000$81.08 MSRP: $113.92You Save: $32.84 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Case Assembly-Oil Seal

Part Number: 21130-3C100$60.25 MSRP: $84.65You Save: $24.40 (29%)Ships in 1-3 Business DaysHyundai Santa Fe Seal-Oil

Part Number: 21421-33144$8.46 MSRP: $10.94You Save: $2.48 (23%)Ships in 1-3 Business DaysHyundai Santa Fe Seal-Oil

Part Number: 21421-35520$14.81 MSRP: $19.15You Save: $4.34 (23%)Ships in 1-3 Business DaysHyundai Santa Fe Seal-Oil Rear

Part Number: 21443-38010$51.25 MSRP: $71.39You Save: $20.14 (29%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 29 Results

Hyundai Santa Fe Crankshaft Seal

If you are looking for affordable high-quality OEM Hyundai Santa Fe Crankshaft Seal, then you have come to the prime place. Our website provides a large amount of genuine Hyundai Santa Fe Crankshaft Seal at unbeatable prices. All our parts come backed with the manufacturer's warranty.

Hyundai Santa Fe Crankshaft Seal Parts Questions & Experts Answers

- Q: How to replace the crankshaft seal on the rear of a four cylinder Hyundai Santa Fe?A:Pull out the transaxle, and then, the driveplate/Flywheel should also be pulled out. Remove the Crankshaft Seal from the rear of the engine utilizing the seal removal tool or a head of screw driver mindfully not to cause any disappointment on the crankshaft or on the seal bore. Wipe out the mating face of the block by using a shop towel; make sure there isn't a single drop of oil or dirt on it. Apply grease on the OD of the seal and place it over the end of the crankshaft with the lip pointing towards the engine. Preferably that the seal installation tool be used to high the new seal into position and indicated that there is a requirement for a small oil drain in the separator to be positioned at the lowest level. If the proper tool is not with you, a large socket can be used to chisel and insert a new seal gently with an aim of getting it flush with the edges of the engine block. Lastly, fit back the driveplate or the flywheel then follow it by fitting the transaxle.

Related Hyundai Santa Fe Parts

Browse by Year

2023 Crankshaft Seal 2022 Crankshaft Seal 2021 Crankshaft Seal 2020 Crankshaft Seal 2019 Crankshaft Seal 2018 Crankshaft Seal 2017 Crankshaft Seal 2016 Crankshaft Seal 2015 Crankshaft Seal 2014 Crankshaft Seal 2013 Crankshaft Seal 2012 Crankshaft Seal 2011 Crankshaft Seal 2010 Crankshaft Seal 2009 Crankshaft Seal 2008 Crankshaft Seal 2007 Crankshaft Seal 2006 Crankshaft Seal 2005 Crankshaft Seal 2004 Crankshaft Seal 2003 Crankshaft Seal 2002 Crankshaft Seal 2001 Crankshaft Seal 2000 Crankshaft Seal