×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Hyundai Parts

- Hyundai Accessories

My Garage

My Account

Cart

Genuine Hyundai Sonata Camshaft

Cam- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

56 Camshafts found

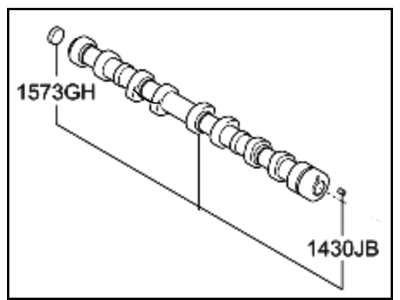

Hyundai Sonata Camshaft Assembly-Exhaust

Part Number: 24200-2G750$250.82 MSRP: $352.39You Save: $101.57 (29%)Ships in 1-3 Business Days

Hyundai Sonata Camshaft Assembly-Intake

Part Number: 24100-25000$184.29 MSRP: $258.92You Save: $74.63 (29%)Ships in 1-3 Business Days

Hyundai Sonata Camshaft-Exhaust,LH

Part Number: 24210-37201$264.50 MSRP: $371.61You Save: $107.11 (29%)Ships in 1-3 Business DaysHyundai Sonata Camshaft Assembly-Intake

Part Number: 24100-2G000$188.49 MSRP: $264.82You Save: $76.33 (29%)Ships in 1-3 Business DaysHyundai Sonata Camshaft Assembly-Intake

Part Number: 24100-2GTB0$201.70 MSRP: $283.39You Save: $81.69 (29%)Ships in 1-3 Business DaysHyundai Sonata Camshaft Assembly-Exhaust

Part Number: 24200-2G000$201.70 MSRP: $283.39You Save: $81.69 (29%)Ships in 1-3 Business DaysHyundai Sonata Camshaft Assembly-Intake

Part Number: 24100-2B770$142.16 MSRP: $199.73You Save: $57.57 (29%)Ships in 1-3 Business DaysHyundai Sonata Camshaft Assembly-Exhaust

Part Number: 24200-2GTA0$201.70 MSRP: $283.39You Save: $81.69 (29%)Ships in 1-3 Business DaysHyundai Sonata Camshaft Assembly-Exhaust

Part Number: 24200-2G620$201.70 MSRP: $283.39You Save: $81.69 (29%)Ships in 1-3 Business DaysHyundai Sonata Camshaft Assembly-Intake

Part Number: 24100-2G600$201.70 MSRP: $283.39You Save: $81.69 (29%)Ships in 1-3 Business DaysHyundai Sonata Camshaft Assembly-Exhaust

Part Number: 24200-2GGA0$250.82 MSRP: $352.39You Save: $101.57 (29%)Ships in 1-3 Business DaysHyundai Sonata Camshaft Assembly-Exhaust

Part Number: 24200-2B770$124.25 MSRP: $174.56You Save: $50.31 (29%)Ships in 1-3 Business DaysHyundai Sonata Camshaft Assembly-Exhaust

Part Number: 24200-2G600$188.49 MSRP: $264.82You Save: $76.33 (29%)Ships in 1-3 Business DaysHyundai Sonata Camshaft Assembly-Exhaust,RH

Part Number: 24700-3C505$290.52 MSRP: $408.18You Save: $117.66 (29%)Ships in 1-3 Business DaysHyundai Sonata Camshaft-Intake,RH

Part Number: 24910-37201$293.46 MSRP: $412.31You Save: $118.85 (29%)Ships in 1-3 Business DaysHyundai Sonata Camshaft-Intake,RH

Part Number: 24910-37211$293.46 MSRP: $412.31You Save: $118.85 (29%)Ships in 1-3 Business DaysHyundai Sonata Camshaft Assembly-Intake

Part Number: 24100-2G650$201.70 MSRP: $283.39You Save: $81.69 (29%)Ships in 1-3 Business DaysHyundai Sonata Camshaft Assembly-Exhaust

Part Number: 24200-2G650$188.49 MSRP: $264.82You Save: $76.33 (29%)Ships in 1-3 Business DaysHyundai Sonata Camshaft Assembly-Exhaust

Part Number: 24200-25000$201.70 MSRP: $283.39You Save: $81.69 (29%)Ships in 1-3 Business DaysHyundai Sonata Camshaft Assembly-Intake

Part Number: 24100-2S000$216.65 MSRP: $304.39You Save: $87.74 (29%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 56 Results

Hyundai Sonata Camshaft

If you are looking for affordable high-quality OEM Hyundai Sonata Camshaft, then you have come to the prime place. Our website provides a large amount of genuine Hyundai Sonata Camshaft at unbeatable prices. All our parts come backed with the manufacturer's warranty.

Hyundai Sonata Camshaft Parts Questions & Experts Answers

- Q: How to remove and insatall Camshaft on V6 Hyundai Sonata?A:On the intake camshaft sprockets, do not dismantle VVTi assembly but shift it fully in or out, to effect its removal or installation, unscrew the center bolt of the camshaft. Bring the engine to TDC, pull the valve cover, and take the timing belt for 2.5L or 2.7L engines, and the Timing Chain for 3.3L engines. When reinstalling the cam sprockets and engine be positive that the two marks made with the sprockets face each other and that camshafts are not inter-changeable. Tighten the camshaft bearing cap bolts by 1/4 of a turn starting with the outer ones followed by the removal of the bearing caps and carefully pulling out the camshaft. Stack the bearing caps properly, if the valve hydraulic adjusters or lifters can be removed then do so and all the components should be laid neatly to be put back. Next, it is necessary to coat the lobes and bearing journals with camshaft installation lubricant, insert lash adjusters in their initial positions. For 2.5L and 2.7L engines, fit the timing chains astride the sprockets and adjust for the timing marks; in 3.3L engines, align each camshaft as it was before and check the position of the timing marks. Locate and orient the bearing caps sequentially with shaft arrows facing the direction of the drivebelt, gradually tighten bolt in a 1/4 turn along with reaching the torque value. Change camshaft oil seal if required, then replace the other parts in reverse order to the present step, be sure the all timing marks match and you do not want to suffer major engine breakdown. As with any automobile, to ensure that there are no leaks and that everything is in proper working order always start the engine, however valve train noise may linger for a while in older models. For checking valve clearance, twist off the valve cover, position the number one cylinder at TDC on the compression stroke side and then using a feeler gauge, check the clearance of the camshaft lobes to the respective lifters. To measure the remaining valves' clearances, rotate the engine one turn clockwise; if any clearances are beyond the limits, remove the camshaft(s) and lifters and measure the thickness of the lifter head and determine correct thickness for replacement lifters. Obtain the correct thickness lifters from the dealer and after fitting check on the clearance measurements to see if they are standard.

Related Hyundai Sonata Parts

Browse by Year

2023 Camshaft 2022 Camshaft 2021 Camshaft 2020 Camshaft 2019 Camshaft 2018 Camshaft 2017 Camshaft 2016 Camshaft 2015 Camshaft 2014 Camshaft 2013 Camshaft 2012 Camshaft 2011 Camshaft 2010 Camshaft 2009 Camshaft 2008 Camshaft 2007 Camshaft 2006 Camshaft 2005 Camshaft 2004 Camshaft 2003 Camshaft 2002 Camshaft 2001 Camshaft 2000 Camshaft 1999 Camshaft 1998 Camshaft 1997 Camshaft 1996 Camshaft 1995 Camshaft 1994 Camshaft 1993 Camshaft 1992 Camshaft 1991 Camshaft 1990 Camshaft 1989 Camshaft 1988 Camshaft