×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Hyundai Parts

- Hyundai Accessories

My Garage

My Account

Cart

Genuine Hyundai Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

407 Pistons found

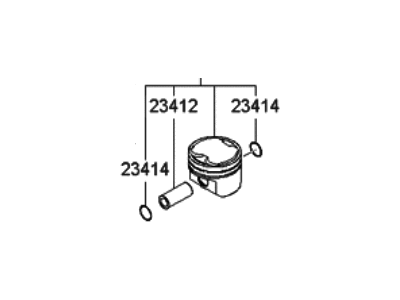

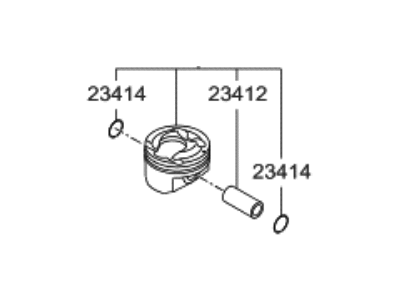

Hyundai Piston & Pin & Snap Ring Assembly

Part Number: 23410-2G501$59.40 MSRP: $83.45You Save: $24.05 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Piston

- Manufacturer Note: STD-A

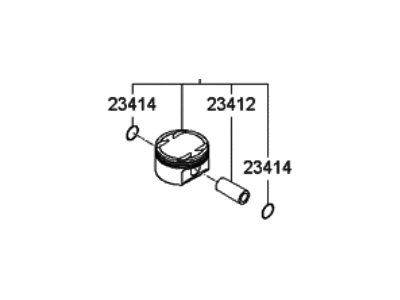

Hyundai Piston & Pin Assembly

Part Number: 23041-2B600$24.74 MSRP: $31.97You Save: $7.23 (23%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Piston

- Manufacturer Note: STD-A

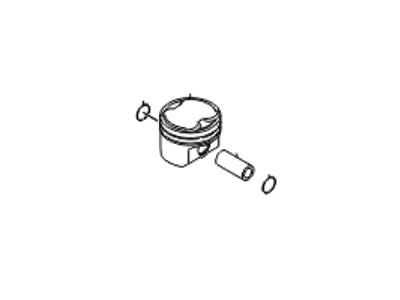

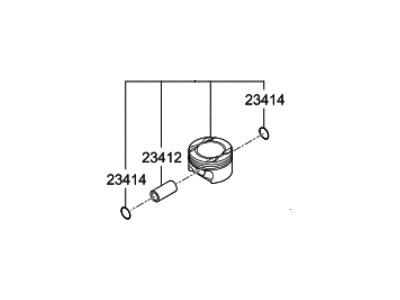

Hyundai Piston & Pin & Snap Ring Assembly

Part Number: 23041-2E200$33.51 MSRP: $46.68You Save: $13.17 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Piston

- Manufacturer Note: STD-A(BLUE)

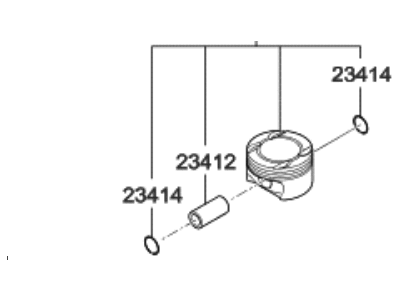

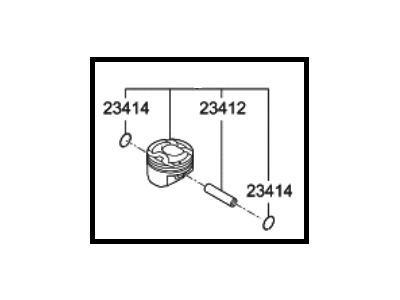

Hyundai Piston & Pin & Snap Ring Assembly

Part Number: 23041-2E800$33.51 MSRP: $46.68You Save: $13.17 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Piston

- Manufacturer Note: STD-A

Hyundai Piston & Pin & Snap Ring Assembly

Part Number: 23410-2G500$59.40 MSRP: $83.45You Save: $24.05 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Piston

- Manufacturer Note: STD-A

Hyundai Piston & Pin Assembly

Part Number: 23410-2G200$60.13 MSRP: $84.48You Save: $24.35 (29%)Ships in 1-3 Business DaysProduct Specifications- Manufacturer Note: STD-A

- Replaced by: 23410-2G201

Hyundai Piston & Pin & Snap Ring Assembly

Part Number: 23041-2E930$67.75 MSRP: $95.19You Save: $27.44 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Piston

- Manufacturer Note: O/SIZE 0.10

Hyundai Piston & Pin & Snap Ring Assembly

Part Number: 23410-2C400$59.40 MSRP: $83.45You Save: $24.05 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Piston

- Manufacturer Note: STD-A

Hyundai Piston & Pin & Snap Ring Assembly

Part Number: 23041-2BAA1$23.96 MSRP: $30.97You Save: $7.01 (23%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Piston

- Manufacturer Note: STD-A

Hyundai Piston & Pin Assembly

Part Number: 23041-2B602$23.96 MSRP: $30.97You Save: $7.01 (23%)Ships in 1-3 Business DaysProduct Specifications- Manufacturer Note: STD-A

Hyundai Piston & Pin Assembly

Part Number: 23410-23982$42.21 MSRP: $58.79You Save: $16.58 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Piston

- Manufacturer Note: O/SIZE 0.50

- Replaces: 23410-23962

Hyundai Piston & Pin & Snap Ring Assembly

Part Number: 23410-2G601$59.40 MSRP: $83.45You Save: $24.05 (29%)Ships in 1-3 Business DaysProduct Specifications- Manufacturer Note: STD-A

Hyundai Piston & Pin & Snap Ring Assembly

Part Number: 23041-3CHN0$44.57 MSRP: $62.08You Save: $17.51 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Piston

- Manufacturer Note: STD-B,RH

Hyundai Piston & Pin & Snap Ring Assembly

Part Number: 23041-3CFA0$44.57 MSRP: $62.08You Save: $17.51 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Piston

- Manufacturer Note: STD-A,LH

Hyundai Piston & Pin & Snap Ring Assembly

Part Number: 23410-2G600$59.40 MSRP: $83.45You Save: $24.05 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Piston

- Manufacturer Note: STD-A

Hyundai Piston & Pin & Snap Ring Assembly

Part Number: 23041-3C700$44.57 MSRP: $62.08You Save: $17.51 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Piston

- Manufacturer Note: STD-A

Hyundai Piston & Pin & Snap Ring Assembly

Part Number: 23041-3C710$44.57 MSRP: $62.08You Save: $17.51 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Piston

- Manufacturer Note: STD-B

- Replaced by: 23041-3C711

Hyundai Piston & Pin & Snap Ring Assembly

Part Number: 23041-3FAA0$45.98 MSRP: $64.05You Save: $18.07 (29%)Ships in 1-3 Business DaysProduct Specifications- Manufacturer Note: STD-A,LH

Hyundai Piston & Pin & Snap Ring Assembly

Part Number: 23410-2G400$60.13 MSRP: $84.48You Save: $24.35 (29%)Product Specifications- Other Name: Piston

- Manufacturer Note: STD-A

Hyundai Piston & Pin & Snap Ring Assembly

Part Number: 23041-2BCA0$47.80 MSRP: $66.58You Save: $18.78 (29%)Product Specifications- Other Name: Piston

- Manufacturer Note: STD-A

| Page 1 of 21 |Next >

1-20 of 407 Results

Hyundai Piston Parts Questions & Experts Answers

- Q: How to piston insatall and rod bearing oil clearance check on Hyundai Elantra?A:On 1.4L and 1.6L engines, the pistons must be installed before the ladder frame. Before installing the piston/connecting rod assemblies, ensure the cylinder walls are clean, the top edge of each cylinder is chamfered, and the crankshaft is in place. Remove the cap from the number one connecting rod, taking care to check the marks made during removal, and wipe the bearing surfaces of the connecting rod and cap with a clean, lint-free cloth. Clean the back side of the new upper bearing insert and lay it in place in the connecting rod, ensuring the tab fits into the recess without hammering it. Clean the back side of the other bearing insert and install it in the rod cap, again ensuring the tab fits into the recess without applying lubricant. Stagger the piston ring gaps around the piston, then slip a section of plastic or rubber hose over each connecting rod cap bolt. Lubricate the piston and rings with clean engine oil, attach a piston ring compressor, and leave the skirt protruding about 1/4-inch to guide the piston into the cylinder. Rotate the crankshaft until the number one connecting rod journal is at bottom dead center and apply engine oil to the cylinder walls. With the mark on top of the piston facing the front of the engine, gently insert the piston/connecting rod assembly into the number one cylinder bore, resting the bottom edge of the ring compressor on the engine block. Tap the top edge of the ring compressor to ensure contact with the block, then gently tap on the top of the piston with a wooden or plastic hammer handle while guiding the connecting rod into place on the crankshaft journal. If resistance is felt, stop immediately to identify the issue. Once installed, check the connecting rod bearing oil clearance before permanently bolting the rod cap in place. Cut a piece of Plastigage slightly shorter than the width of the connecting rod bearing and lay it on the number one connecting rod journal. Clean the connecting rod cap bearing face, remove the protective hoses, and install the rod cap, ensuring the mating marks align. Tighten the nuts in three steps, using a thin-wall socket to avoid erroneous torque readings. Remove the nuts and detach the rod cap carefully to avoid disturbing the Plastigage, then compare the width of the crushed Plastigage to the scale on the envelope to obtain the oil clearance. If the clearance is not as specified, check for dirt or oil between the bearing inserts and the connecting rod or cap, and recheck the journal diameter. Carefully scrape all traces of Plastigage off the rod journal and bearing face without scratching the bearing. Apply a uniform layer of clean moly-base grease or engine assembly lube to both bearing faces, push the piston into the cylinder to expose the bearing insert face, and slide the connecting rod back into place on the journal. Remove the protective hoses, install the rod cap, and tighten the nuts to the torque in three steps. Repeat the procedure for the remaining pistons/connecting rods, ensuring the back sides of the bearing inserts and the insides of the connecting rods and caps are clean, the correct piston/rod assembly is used for each cylinder, the arrow on the piston faces the front of the engine, and the cylinder walls and bearing faces are lubricated. After all assemblies are installed, rotate the crankshaft by hand to check for binding, and finally, check the connecting rod endplay, comparing the measured endplay to ensure it is correct. If new rods or a new crankshaft were installed, inadequate endplay may require resizing at an automotive machine shop.

Related Hyundai Parts

Browse by Model

Accent Piston Azera Piston Elantra GT Piston Elantra N Piston Elantra Piston Elantra Touring Piston Entourage Piston Equus Piston Excel Piston Genesis Coupe Piston Genesis G70 Piston Genesis G80 Piston Genesis G90 Piston Genesis GV70 Piston Genesis GV80 Piston Genesis Piston Ioniq Piston Kona N Piston Kona Piston Palisade Piston Santa Cruz Piston Santa Fe Hybrid Piston Santa Fe Piston Santa Fe Sport Piston Santa Fe XL Piston Scoupe Piston Sonata Hybrid Piston Sonata Piston Tiburon Piston Tucson Piston Veloster N Piston Veloster Piston Venue Piston Veracruz Piston XG300 Piston XG350 Piston